Industrial Scrubbers

Wet Scrubbers, Dry Scrubbers, and Electrostatic Precipitators

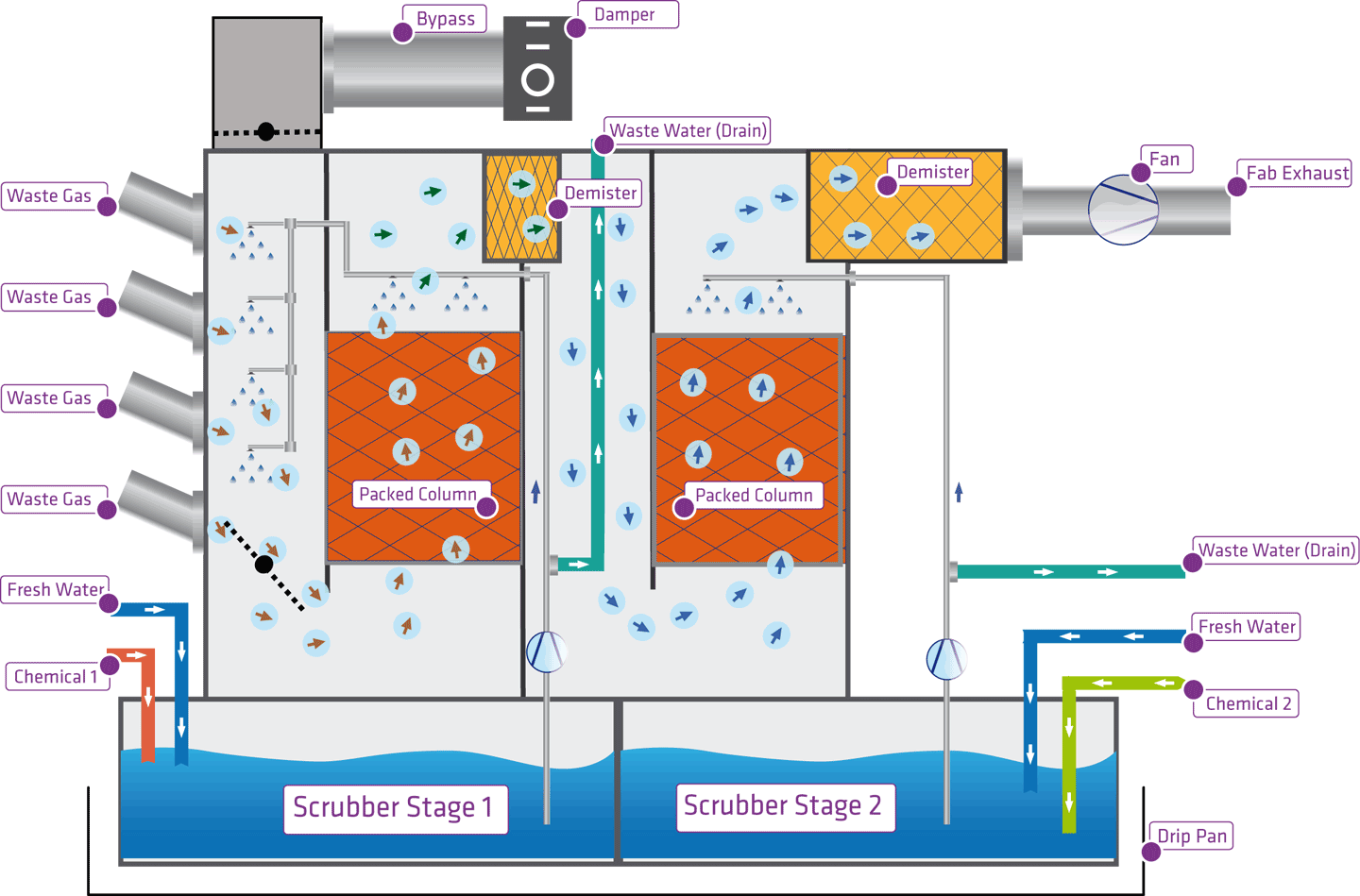

Scrubbers are air pollution control devices that use liquid to remove particulate matter or gases from an industrial exhaust or flue gas stream. This atomized liquid (typically water) entrains particles and pollutant gases in order to effectively wash them out of the gas flow.

In comparison to other air pollution control devices, scrubbers are very multidisciplinary, with the ability to remove solids, mists, and gases simultaneously while also providing cooling. They are also capable of handling explosive and flammable gases safely. However, scrubbers suffer from high levels of corrosion and produce slurry waste streams which are less convenient for recycling and disposal.

Wet Industrial Scrubbers

One of the most basic of the various industrial scrubbers is the wet industrial scrubber. In its most basic form, water is encapsulated in a metal or composite container. Contaminated gas is passed through the water, and the water absorbs the contaminates. Other liquids can be used to effectively remove varied contaminates. These liquids differ in the chemical composition and the overall charge. These liquids can be anything from highly positively or negatively charged to non-charged. Because pollutants can differ in their charge, scrubbers can be packed with a liquid that will bind most effectively to remove the contaminate from the gas.

The gas exiting the scrubber is thus cleaner. Developments in wet scrubbers have allowed for increased efficiency in pollutant removal. One of the major developments has been to maximize the total surface of the liquid with which the polluted gas associates. More surface area means that more of the contaminates can be pulled out of the gas. Another development in scrubbers has been increasing the mixture of the gas with the scrubber fluid. These aspirators agitate the solution and increase the mixing of the polluted gas and the liquid.

The wet scrubber differs from the other different types of industrial scrubbers because the liquid-gas association increases the moisture level of the gas that is being expelled from the scrubber. The increased moisture in the gas will create a visible cloud exiting the scrubber.

Operating Principle of Wet Scrubber Image.. www.das-europe.com

Dry Industrial Scrubbers

Unlike wet industrial scrubbers, dry scrubbers do not utilize a liquid to absorb contaminants. Because of this difference, steam is not produced by the reaction, and a wastewater system is not needed. A dry industrial scrubber is composed of a reaction center where the sorbent or dry reaction material that absorbs contaminants is mixed with the polluted gas. Also within the system is a material component that aids in the removal of the reaction product, which is the dry sorbent bound to the pollutant. Dry scrubbers are used primarily to remove acids found within gasses.

The dry sorbent used to remove the acid from the gas is usually made of an alkaline slurry. This slurry is basic in nature and will neutralize the acid found in the gas. This sorbent can be mixed with the acid gas in two ways. There are two different types of dry industrial scrubbers. The first is called dry sorbent injection. During this process, the gas is mixed directly with the alkaline sorbent. The second method is the spray dryer absorbent method. In this method, the contaminated gas is processed through a mist of the sorbent. The sprayer allows for a good mixture and efficient removal of the pollutants from the gas.

Electrostatic Precipitators

Electrostatic precipitators function uniquely from the different types of industrial scrubbers by using charged energy to remove dust and other contaminates from a gas. It is important to match the polarity and type of charge to bind to and remove the pollutants from the gas. An example of the design of an electrostatic precipitator is a plate precipitator. The plate is a sheet of metal that is charged with a specific type of charge. These plates are designed to run parallel with the piping so that the gas will pass through by the plates and the plates will remove the dust or contaminate.

In addition to metal plate electrostatic precipitators, there are also wet electrostatic precipitators that help to remove high moisture gases. Some of the chemicals that can be removed from gas include sulfuric acid. The resultant slurry that contains the bound pollutant is rotated away from the electrostatic precipitator to remove the contaminates and maintain an effective charged surface for pollutant removal.

Products of the Different Types of Industrial Scrubbers

The products of scrubbers can either be a hazardous waste product or a useful product. In many cases, the scrubber and downstream processing is able to create a solid slurry that is separated from the purified gas. In most cases, the pollutant product will need to have further processing in order to be become a useful end product. An example of a useful product includes gypsum extracted from scrubbers used in coal power plants. This synthetic gypsum can be used as a component of drywall. Companies should be careful to understand the byproducts of their scrubbers and dispose properly of the hazardous waste. Recycling the waste can be a great option to either save on hazardous waste disposal or make money on a byproduct. Secondary processors of scrubber byproducts will actually haul away waste and in certain cases pay a price for the slurry.

Industrial Scrubbers Protect the Environment

The different types of industrial scrubbers help protect the environment by removing harmful chemicals and acids from polluted gas. There are multiple types of scrubbers that aid in this process, including wet, dry, and electrostatic scrubbers. With efficient, well-maintained industrial scrubbers, a facility can complete production and protect the community and their workers. In certain cases, these scrubbers remove pollutants that can be processed and be profitable as end products themselves. STI Group services and maintains dependable industrial scrubbers.

Advantages and Disadvantages of Scrubbers

Advantages

- Can handle flammable and explosive dusts with little risk

- Provides gas absorption and dust collection in a single unit

- Provides cooling of hot gases

- Compact; can often be retrofitted into existing collection systems

- Corrosive gases and dusts can be neutralized

Disadvantages

- High potential for corrosion problems

- Collected particulate may be contaminated and unrecyclable

- Protection against freezing required. Certain streams may require reheating to avoid visible plume

- Disposal of waste sludge can be very expensive

- Requires makeup water to replace purged liquid and disposed sludge

References.. setxind.com, kingtoolcompany.com, das-europe.com

1960

1960