Dimensions of Spiral Wound Gaskets ASME B16.20

used with Raised Face flanges ASME B16.47 series A

OTHER PRESSURE CLASSES

600

| NPS | Inner Ring | Sealing Element | Outer Ring | |

| d1 | d2 | d3 | d4 | |

| 26 | 647.7 | 685.8 | 736.6 | 866.9 |

| 28 | 698.5 | 736.6 | 787.4 | 914.4 |

| 30 | 755.7 | 793.8 | 844.6 | 971.6 |

| 32 | 812.8 | 850.9 | 901.7 | 1022.4 |

| 34 | 863.6 | 901.7 | 952.5 | 1073.2 |

| 36 | 917.7 | 955.8 | 1006.6 | 1130.3 |

| 38 | 952.5 | 990.6 | 1041.4 | 1104.9 |

| 40 | 1009.7 | 1047.8 | 1098.6 | 1155.7 |

| 42 | 1066.8 | 1104.9 | 1155.7 | 1219.2 |

| 44 | 1111.3 | 1162.1 | 1212.9 | 1270 |

| 46 | 1162.1 | 1212.9 | 1263.7 | 1327.2 |

| 48 | 1219.2 | 1270 | 1320.8 | 1390.7 |

| 50 | 1270 | 1320.8 | 1371.6 | 1447.8 |

| 52 | 1320.8 | 1371.6 | 1422.4 | 1498.6 |

| 54 | 1378 | 1428.8 | 1479.6 | 1555.8 |

| 56 | 1428.8 | 1479.6 | 1530.4 | 1612.9 |

| 58 | 1473.2 | 1536.7 | 1587.5 | 1663.7 |

| 60 | 1530.4 | 1593.9 | 1644.7 | 1733.6 |

General notes..

- Dimensions are in millimeters unless otherwise indicated.

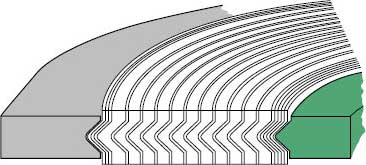

- Image shows a Spiral Wound gasket with Inner - and Outer ring.

- d1 = Inside diameter when Inner ring is used.

- d2 = Inside diameter sealing element when no Inner ring is used.

- d3 = Outside diameter of sealing element.

- d4 = Outside diameter of Outer ring.

- The gasket thickness tolerance is ± 0.13 mm measured across the metallic portion of the gasket, not including the filler, which may protrude slightly beyond the metal.

- The gasket inside diameter tolerance for NPS 26 through NPS 34 is ± 0.8 mm, and the tolerance for NPS 36 through NPS 60 is ± 1.3 mm.

- The gasket outside diameter tolerance for NPS 26 through NPS 60 is ± 1.5 mm.

- The centering ring outside diameter tolerance is ± 0.8 mm.

- The inside diameter tolerance is ± 3.0 mm.

- Thickness of inner and outer ring.. 2.97 mm - 3.33 mm.

- ASME B16.47 Series A flanges NPS 12 through NPS 24 have the same raised face dimensions as ASME B16.5 flanges.

- There are no Class 900 flanges NPS 50 and larger.

Marking of Spiral Wound Gaskets