Introduction

Nord Stream, until 2006 Northern European Gas Pipeline (NEGP) is a dual gas pipeline to transport Russian natural gas through the Baltic Sea to Germany. The construction was started on December 9, 2005 and the gas in the first conduit began to flow on November 8, 2011.

Nord Stream (former names - North Transgas and North European Gas Pipeline) is an offshore natural gas pipeline from Vyborg in Russia to Greifswald in Germany. It is owned and operated by . The name occasionally has a wider meaning, including the feeding onshore pipeline in Russia, and further connections in Western Europe.

The project, which was promoted by the government of Russia and agreed to by the government of Germany, was seen as controversial for various reasons, including increasing European energy dependence on Russia and potential environmental damage.

The project includes two parallel lines. The first line of the pipeline was laid by May 2011 and was inaugurated on 8 November 2011. The second line was laid in 2011-2012 and was inaugurated on 8 October 2012. At 1,222 kilometres (759 mi) in length, it is the longest sub-sea pipeline in the world.

Technical features

Russian onshore pipeline - Construction of the feeding pipeline in Russia (Gryazovets-Vyborg gas pipeline) began on 9 December 2005 in the town of Babayevo in Vologda Oblast. It was completed in 2010. This pipeline is operated solely by Gazprom. It is a part of the integrated gas transport network of Russia connecting existing grid in Gryazovets with the coastal compressor station at Vyborg. The length of this pipeline is 917 kilometres (570 mi), the diameter of the pipe is 1,420 millimetres (56 in), and working pressure is 100 standard atmospheres (10 MPa), which is secured by six compressor stations. The Gryazovets-Vyborg pipeline, parallel to the branch of the Northern Lights pipeline, also supplies gas to the Northwestern region of Russia (Saint Petersburg and Leningrad Oblast). A branch pipeline in Karelia will connect this feeding pipeline with Finland.

Baltic Sea offshore pipeline - Two pipes are welded together on the Castoro Sei pipelaying vessel. The Nord Stream offshore pipeline is ordered and operated by . It runs from Vyborg compressor station at Portovaya Bay along the bottom of the Baltic Sea to Greifswald in Germany. The length of the subsea pipeline is 1,222 kilometres, of which 1.5 kilometres in Russian inland, 121.8 kilometres in Russian territorial waters, 1.4 kilometres in the Russian economic zone, 375.3 kilometres in the Finnish economic zone, 506.4 kilometres in the Swedish economic zone, 87.7 kilometres in the Danish territorial waters, 49.4 kilometres in the Danish economic zone, 31.2 kilometres in the German economic zone, 49.9 kilometres in German territorial waters and 0.5 kilometres in German inland. The pipeline has two parallel lines, each with capacity of 27.5 billion cubic metres of natural gas per year. Pipes have a diameter of 1,220 millimetres (48 in), the wall thickness of 38 millimetres (1.50 in) and a working pressure of 220 bars (22 MPa).

Western European pipelines - The Western European part of the project includes two transmission pipelines in Germany. The southern pipeline (OPAL pipeline) runs from Greifswald to Olbernhau near German-Czech border. It connects Nord Stream with JAGAL (connected to the Yamal-Europe pipeline), and STEGAL (connected to the Russian gas transport route via Czech and Slovak republics) transmission pipelines. The Gazelle pipeline, put into operation in January 2013, links the OPAL pipeline with South-German gas network.

The western pipeline (NEL pipeline) runs from Greifswald to Achim, where it will be connected with the Rehden-Hamburg gas pipeline. Together with the MIDAL pipeline it will create the Greifswald-Bunde connection. Further gas delivery to the United Kingdom will be made through the planned connection between Bunde and Den Helder, and from there through the offshore interconnector Balgzand-Bacton (BBL Pipeline).

Gazprom has also bought an abandoned mine (Hinrichshagen Structure) in Waren, which is planned to convert into the largest underground gas storage in Europe with capacity of 5 billion cubic metres.

Nord Stream AG and Shareholders

Project Players

Nord Stream Gas Purchasers

- Gazprom Marketing and Trading Ltd, UK

- DONG Energy A/S

- GDF SUEZ S. A.

- WINGAS GmbH and Co. KG

- E.ON Ruhrgas AG

Logistics

- EUPEC

- Port of Sassnitz-Mukran

- Port of Kotka

- Port of Hanko

- Port of Slite

- Port of Karlskrona

Pipes and Materials

- EUROPIPE

- OMK

- Sumitomo

- Petrol Valves

Environmental Studies, Quality Management and Safety

- Marin Mätteknik

- Rambøll

- DoF

- PeterGaz

- ERM

- DNV

- FOGA

- SGS TÜV

Construction

- Saipem

- Allseas

- Van Oord

- Boskalis-Tideway

- Rohde Nielsen

Operations

- Technip

- Statoil

- Siemens

- IMPaC

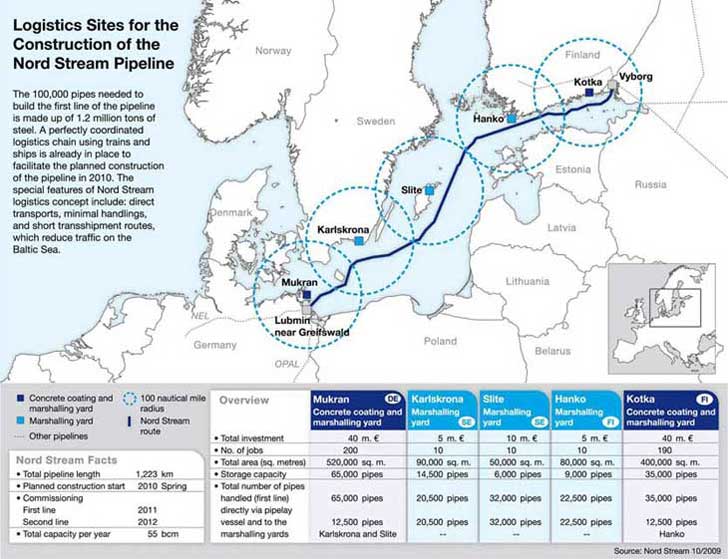

Concrete weight coating & logistics services were provided by EUPEC PipeCoatings S.A. For the concrete weight coating new coating plants were constructed in Mukran (Germany) and Kotka (Finland). Rolls-Royce plc supplied eight industrial aeroderivative gas turbines driving centrifugal compressors for front-end gas boosting at the Vyborg (Portovaya) gas compressor station. Dresser-Rand Group supplied DATUM compressors and Siirtec Nigi SPA provided a gas treatment unit for the Portovaya station.

For the construction period, created a logistic center in Gotland. Other interim stock yards are located in Mukran, in Kotka, in Hanko (Finland) and in Karlshamn (Sweden).

Reference(s) for the images and text, is owned by Nord Stream AG

Other Pages

Part 1..

Nord Stream Introduction

Part 2..

Preparation for pipe laying

Part 3..

Manufacturing of Large Steel Components

Part 4..

Logistics by the Numbers

Part 5..

Pipe Laying Vessel..

Saipem's Castoro Sei

Part 6..

Pipe Laying Vessel..

Saipem's Castoro Dieci

Part 7..

Pipe Laying Vessel..

Allseas Solitaire

Part 8..

Pipelaying Processes

Part 9..

Tie-Ins and Hyperbaric welding

Part 10..

Pre-Commissioning and Pressure Testing