|

Manhole(s) in Process Piping |

A manhole is installed in storage tanks, pressure vessels, drums, columns and serves as a passage and vent for personnel during installation, repair, cleaning and maintenance.

Manholes should be at least 24 inches diameter to be practical from a safety viewpoint. This has

been found to be the minimum size for a man with an airpack and tools to gain safe internal access.

When a manhole opening is made in a vessel or shell; the shell becomes weaker due to the amount

of metal removed.

Therefore a reinforcing pad is

provided by welding around the opening.

Manholes come in all shapes and sizes, but this article will briefly describe only the 2 most common in process piping.

Manhole with cover for vertical applications

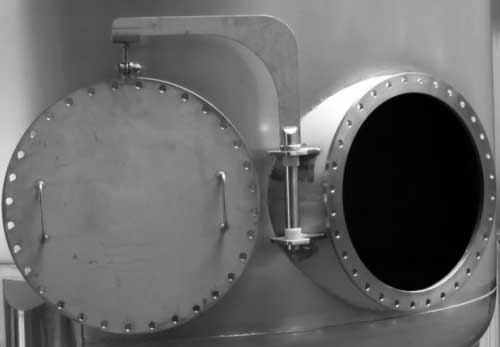

This type is mounted on the side(s) of drums, pressure vessels, storage tanks or columns. Closing or opening the manhole is done by means of a blind flange connected to a swivel device. If all bolts from the flange connection blind and manhole flange removed the blind flens can be simply separated from the manhole with the swivel device.

The swivle device in pipeline terms is called a Davit. A Davit (especially for manholes) is a mechanically designed hinged guide and support system that facilitates the opening and closing of large and heavy blind flanges. This system can be designed for horizontal and vertical applications. In principle, a Davit can also be applied to other flanges such as the cover of a shell and tube heat exchanger etc.

A blind flange 24 inch e.g. class 150 is about 200kg, so no additional lifting equipment is needed, with the use of a Davit.

Manhole

24inch with a Davit for vertical application

Manhole

24inch with a Davit for vertical application Manhole with cover for horizontal applications

This type is mounted on the top of drums, pressure vessels or columns. Closing or opening of the manhole is done in the same way as described for the manhole for vertical application.

Manhole

24inch with a Davit for horizontal application

Manhole

24inch with a Davit for horizontal application Davit for Manhole

Example of Manholes in Distillation Columns

Manholes in a column with trays are normally provided at the top, below the lower tray, at the supply tray and at any other tray around which there are removable internal parts. Passage at intermediate points should be placed so that the maximum distance between two passages does not exceed 15 trays.

There are obvious and logical reasons for installing manholes in distillation columns. There must be limited access to inspect, clean and repair the column from time to time. This can be important, especially when liquids are distilled that can corrode, clog, erode or cause damage in the column.

Some rules of thumb..

- To have mobility and space to work in a column, the column must have an inner diameter of at least 1220 millimeters - preferably at least 1520mm. The distance between trays in the column must be at least 610mm. Otherwise, a person cannot maneuver inside and work safely or quickly exit the column in case of an emergency. These are important and critical points to always keep in mind when engineering a column. If you instruct a worker to enter a confined space, you are morally obligated to ensure that he can safely enter, work and exit the confined space.

- Any column less than one meter in diameter normally has fixed, bolted or welded trays (unless it is packaged). In that case, you will also find that it is impractical to expect a human being to safely enter the 1 meter-diameter column. You will have to decide whether to install a manhole at each tray - including the usual one for the collection tray - or to permanently seal each tray and forget about access to it. For a small-diameter column, you can always consider a gasket - especially a structured gasket.

This short example has hopefully given an impression of the need for manholes.

Please also read the safety article on entering of Confined spaces

Related Post(s)

A gas flare, alternatively known as a flare stack is a important safety device used in refineries and petrochemical facilities...