|

Plate Heat Exchanger |

History

The first commercially successful plate-and-frame Heat Exchanger in the world was introduced in 1923 by Dr. Richard Seligman, the founder of the Aluminum Plant and Vessel Company Ltd., commonly known today as APV. The very first Paraflow Plate and Frame Heat Exchanger was constructed of cast gunmetal plates and enclosed within a frame that set the standard for today's computer-designed thin metal plate Heat Exchanger known around the world.

Function of a Plate Heat Exchanger

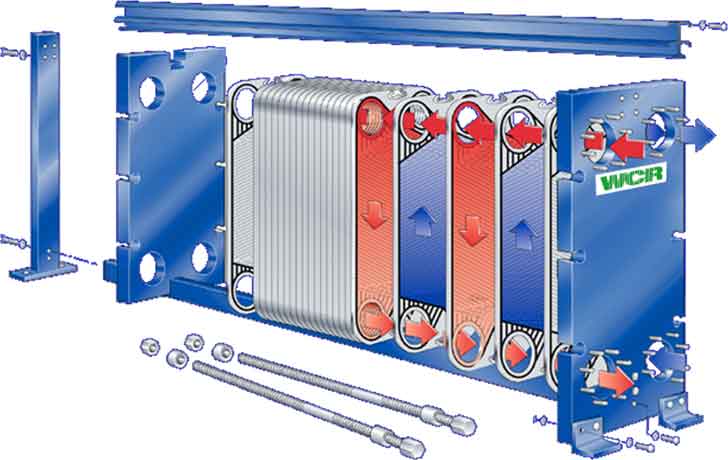

A plate Heat Exchanger is a unit which transfers heat continuously from one media to another media

without adding energy to the process. The basic concept of a plate and frame Heat Exchanger is two

liquids flowing on either side of a thin corrugated metal plate so heat may be easily transferred

between the two.

The plates are compressed by means of tie bolts between a stationary frame part (called the head)

and a movable frame part (called the follower).

The plate Heat Exchanger efficiency requires less floor space compared to other types of Heat Transfer

equipment and is lighter in weight.

Image is owned by WCR

Design of a Plate Heat Exchanger

The plate Heat Exchanger is designed with either single-pass or multi-pass flow, depending on the duty. For most duties single-pass is suitable and often the preferred solution as it keeps all connections on the stationary frame part and consequently makes disassembly easier. Multi-Pass however, is required when flow rates are low or when approach temperatures are close. Other factors such as building ceiling height or space limitations for handling of large plates often leads to the decision to use multi-pass and thereby more and smaller plates.

Types of a Plate Heat Exchangers

Paraflow Plate Heat Exchangers

The Paraflow is the original plate type Heat Exchanger designed by APV to provide maximum efficiency

and cost effectiveness in handling a wide variety of Heat Transfer applications. Units come in

different configurations, as follows..

- Single Wall Gasketed (Paraflow) Plate Heat Exchangers - The traditional plate and frame Heat Exchanger

- Double Wall (Duo-Safety) Plate Heat Exchangers - Used to prevent cross contamination of the fluids

- Semi-Welded (Paraweld) Plate Pair Plate Heat Exchangers - No gaskets on one plate channel, gasket on the other side for the ultimate in flexibility and safety

ParaBrazed Plate Heat Exchangers

ParaBrazed Heat Exchangers are a compact, cost effective unit designed to deliver high thermal efficiency

while maintaining lower pressure drops. It's the perfect choice for many single and two phase Heat

Transfer applications for industrial and refrigeration duties.

Hybrid Heat Exchanger - All Welded Design

All welded Hybrid Heat Exchangers combines the advantages of a plate and frame Heat Exchanger with

those of a tubular exchanger.

Plate Heat Exchanger - Working Principle

Advanges of Plate Heat Exchangers

Easy to Remove and Clean

- Plate Heat Exchangers are easy to clean by remove the tie bolts and slide back the movable frame part. Then the plate pack can be inspected, pressure cleaned, or removed for refurbishment if required.

Expandable

- A very significant feature of the plate Heat Exchanger is that it is expandable. Increasing the Heat Transfer requirements means simply adding plates instead of buying a new Heat Exchanger, saving time and money.

High Efficiency

- Because of the pressed patterns in the plates and the relative narrow gaps, very high turbulence is achieved at relative low fluid velocity. This combined with counter directional flow results in very high Heat Transfer coefficients.

Compact Size

- As a result of the high efficiency, less Heat Transfer area is required, resulting in a much smaller Heat Exchanger than would be needed for the same duty using other types of Heat Exchangers. Typically a plate Heat Exchanger requires between 20-40% of the space required by a tube and shell Heat Exchanger.

Close Approach Temperature

- The same features that give the plate Heat Exchanger its high efficiency also makes it possible to reach close approach temperatures which is particularly important in heat recovery and regeneration applications. Approach temperatures of 0.5°C is possible.

Multiple Duties in a Single Unit

- The plate Heat Exchanger can be built in sections, separated with simple divider plates or more complicated divider frames with additional connections. This makes it possible to heat, regenerate, and cool a fluid in one Heat Exchanger or heat or cool multiple fluids with the same cooling or heating Reference(s).

Less Fouling

- Very high turbulence is achieved as a result of the pattern of the plates, the many contact points, and the narrow gap between the plates. This combined with the smooth plate surface reduces fouling considerably compared to other types of Heat Exchangers.

Lower Costs

- High Heat Transfer coefficients mean less Heat Transfer area and smaller Heat Exchangers, and sometimes even less Heat Exchanger.

Reference.. WCR