|

Flange Insulation Gasket Kit |

Flanges are the most challenging element in the design of a piping system. To prevent leakage from flanges, extra care must be taken to seal them properly. For example, in the Netherlands, most chemical and petrochemical companies require a so-called flange fitter certificate.

The flange fitter is trained to work according to protocol, and is responsible for the dis- and assembly of flange connections in piping systems. Specifically for this purpose, a number of companies offer training, for a flange fitter course according to protocol.

Gasket sets for flange insulation are designed to ensure the integrity and reliability of the pipeline and piping system through safety and corrosion protection. By eliminating metal-to-metal contact, static flow is stopped to prevent corrosion and aid in the cathodic protection of the piping system.

Flange insulation gasket kits provide both effective sealing and reliable electrical insulation of flanges. Made of high-quality materials with high dielectric constant and low water absorption. Flange insulation gaskets kits are available in different configurations to meet any possible need. Flange insulation gasket kits come in all DIN, ASME and API classes.

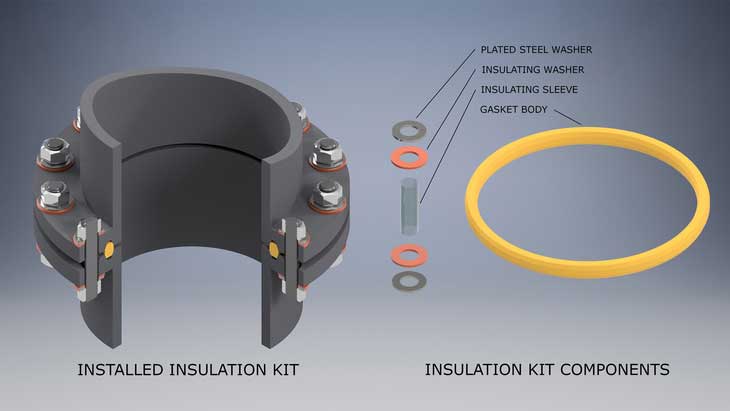

Parts of flange insulation kit

Each flange insulation kit consists of..

1 central flat or oval gasket

1 insulating sleeve for each bolt

2 insulating steel washers for each bolt

2 sheet steel washers for each bolt

All these parts are made of unique materials with chemical stability, dielectric properties and minimal water absorption to achieve the purpose. Complete sets are individually packaged and labeled with flange size, rating, type and material combination. Insulation sets are normally accessible up to 24 inches, but custom higher nominal sizes can be manufactured upon request.

Type E

A 3,2 mm (1/8 inch) thick plated steel washer

B 3,2 mm (1/8 inch) thick insulating washer

C Full length insulating sleeve

D Full face Gasket

This style kit contains a full face gasket that has the same outside diameter as the flanges. This style gasket will prevent foreign material from collecting and creating a bridge, thus shorting the cathodic isolation. Type E gaskets are available in, neoprene-faced phenolic, and high temperature materials.

Type F

A 3,2 mm (1/8 inch) thick plated steel washer

B 3,2 mm (1/8 inch) thick insulating washer

C Full length insulating sleeve

D Inner Bolt Circle Gasket

This gasket fits the raised face flanges. The outside diameter of the gasket is slightly smaller than the inside diameter of the bolt circle. This gasket can be used on both raised and full flanges. Type F gaskets are available in neoprene-phenol and high-temperature materials. (It is recommended that flanges be wrapped with flange band protectors to prevent foreign material from collecting and forming a bridge, shorting the insulation).

Type D

A 3,2 mm (1/8 inch) thick plated steel washer

B 3,2 mm (1/8 inch) thick insulating washer

C Full length insulating sleeve

D Insulating Ring type joint

Type D gaskets are designed to fit into the ring groove of RTJ (ring type joint) flanges.

Insulating gasket material

Materials must be chosen that will ensure long-term effective sealing and electrical insulation of flange connections. Sometimes, gaskets are made with combinations of materials to create the best characteristics.

Normal gasket materials are G3, G7, Nitrile, Plain Phenolic, G10, Neoprene faced Phenolic, Teflon, Durlon, etc.

Popular Sleeve materials are Phenolic, Mylar, Polyethylene, Minlon and so on.

Ring materials can be Phenolic, Steel, G7, G3 and so on.

Installation of the flange insulation gasket kit

The essential parts of the insulation gasket kit are the polyethylene insulation sleeve and the mounting piece. Compared to the standard technique of flange connections with bolts and nuts, the insulation kit uses a stud with a washer and a nut at each end of the flange connection. The insulator sleeve is then inserted into the bolt holes, one insulator on each side of the flange.

Consequently, two insulators are inserted into the flange per bolt hole. The mounting piece is then inserted into the insulating sleeves until the threads are visible at both ends of the stud outside the flange. A flat steel washer is placed on each end of the stud, and a nut is turned on each end of the stud.

The flange insulation kit becomes significantly stronger than a connection with hex bolt and nut because a nut is tightened at each end of the stud. When tightening a nut-and-bolt, all of the clamping force is applied to the single set of threads on the bolt. However, when tightening a stud with two ends, such as in a flange isolation kit, the clamping force is equally distributed between the threads on both ends of the stud and inside both nuts.

The stud is shielded and insulated against electrical charge or corrosion. This results in a flange connection that will not corrode or fail due to chemical interaction between two different metals.