|

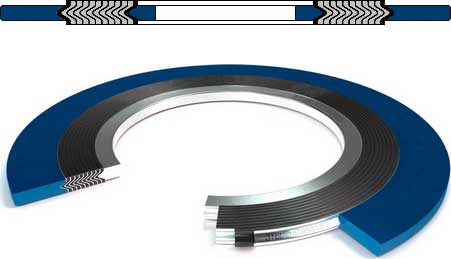

DishinG Spiral Wound Gaskets |

Some time ago the question was asked on my forum: Why does the outer ring of a spiral wound gasket (with inner and outer rings) sometimes get warped (like a satellite dish) when installed?

I had seen this phenomenon before, but any flange connection with a warped gasket was leak-free, both during hydro or service testing, and also later under operating conditions.

What I did note at the time was, the gaskets were deformed only at pressure classes 400 and above, and were torqued with professional bolting equipment.

At one point I just accepted that phenomenon, until the above mentioned question was asked. Then I consulted many colleagues, suppliers, etc., but no one could give me a satisfactory answer.

After months, by chance, I had contact with an Application Engineer from the Eriks company in the Netherlands. I told my story, and a few days later I found the following message in my email inbox.

Hi Werner,

The 'problem' of dishing is a situation that frequently occurs when installing a spiral wound gasket.

The centering ring serves to center the gasket between the bolts and also serves as a compression

stopper.

The initial thickness of the spiral wound seal is about 4.5mm, and is compressed to about 3.2mm.

This compression produces high radial stresses exerted on the inner and outer rings.

When the gasket is completely well centered between the flanges, the centering ring may be clamped

between the flanges by a very small amount or not at all.

Due to radial tension and the fact that the ring is not clamped between the flanges, the centering

ring is pushed outward causing dishing.

Dishing will only occur when there is sufficient bolt load that the gasket is properly compressed

to the centering ring/inner ring.

The part that has little or no clamping between the raised face parts will in many cases be at

the bottom.

This is because the gasket drops down during assembly.

There is a clearance of 3.2mm between pitch circle of bolt holes, bolt size and outer diameter

gasket.

For example for the size 12inch 150lbs, the OD spiral section is 14.75 inches (374.65mm), the OD

raised face is 15 inches (381mm).

When the seal is sunk all the way down, the raised face portion rests at only 1.6mm. It is important

that the seal is pressed down to the centering ring.

However, dishing does not affect the sealing properties and therefore does not cause integrity

problems.

Also, I have a customer where they are required to have the outer ring cupping so they know there

is sufficient surface pressure on the gasket.

Kind regards,

Angelo

Thank you Angelo

Related Post(s)

Spiral wound gaskets are characterised by a high degree of precision. This makes it possible to integrate a filler material while winding a profiled metal strip...