|

Post Weld Heat Treatment (PWHT) |

PWHT - short for Post Weld Heat Treatment - is the more familiar and international name for what is also known as low-stress annealing. Such heat treatment is often used to minimize thermal stresses in the steel after welding. In some projects, this process itself is a requirement.

What exactly is PWHT?

Before we go further into the technical specifications, it is useful to know what exactly PWHT is. Simply translated, it is a heat treatment performed after welding operations. The treatment consists of a controlled process in which the workpiece is heated to a certain temperature and held.

The heat changes the properties of the workpiece material, such as the force that can be applied to it. The temperature is just below a critical point, at which point there is a chance of transformation of the material (such as melting) - something that must obviously be prevented. The temperature is determined according to the type of material, the thickness of the workpiece and the desired modifications, among other things.

With PWHT, your workpiece is heated slowly, kept at temperature and also cooled slowly again. Among other things, this reduces the stresses in the material that occur after welding. By reducing the stresses, you prevent cracks or fractures from forming as soon as the workpiece is to be worked on. Thus, safety and reliability can be guaranteed when applying low-tension annealing.

PWHT can be a free choice, but is also often a requirement for certain projects. Think of projects in the (petro)chemical, boiler and equipment construction and offshore, where for example, structures or storage tanks must meet strict requirements of a quality mark. An insurer may also require that such projects undergo a PWHT process.

How does the PWHT process work?

Whether a workpiece should undergo PWHT and how long this treatment takes depends on certain factors. Among other things, the material, alloy system and thickness play into this consideration. In addition, any previous treatments must be taken into account.

Even when building a workpiece - such as a storage tank or heat exchanger - a fabricator must already carefully consider what type of material to use. This is because it is inherent in which heat treatment is needed to preserve or enhance the material's properties. After all, it goes without saying that the structure must not deform or melt.

Preheating

Preheating, as defined in the American Welding Society (AWS) Standard Welding Terms and Definition, is the heat applied to the base metal or substrate to achieve and maintain the preheat temperature.

Preheat temperature is defined in the same document as the temperature of the base metal in the volume surrounding the weld point immediately before welding is started. In multilayer welding, it is also the temperature immediately before the second and subsequent layers are started (interpass temperature).

How should preheating be performed?

For preheating, gas burners, oxygen gas flames, electric blankets, induction heating or heating in an oven can be used. For excellent results, uniform heating around the joint is critical. Intensive, non-uniform heating is of little use in delaying cooling and may cause higher residual stresses, distortion or undesirable metallurgical changes in the base material.

When preheating is specified, the entire weld joint must be heated uniformly throughout the material thickness to the desired minimum temperature. To obtain an even temperature over the entire material thickness, it is desirable to apply heat source to one side of the material surface and measure the material temperature on the other side.

Whenever heating and temperature measurement are to be made from the same surface, the inspector must ensure that more than just the surface of the material has been heated. It is important to ensure that the material is heated to a uniform temperature throughout its thickness.

In addition to setting a preheat temperature, an interpass temperature limitation may need to be considered for some applications. This information should be reflected in the welding procedure specification. When an interpass temperature is specified, the weld site should be inspected before the next weld bead is applied. Welding should not proceed if the measured temperature exceeds the maximum interpass conditions specified in the welding procedure. The weld must be allowed to cool to the specified upper limit of the interpass temperature before further welding.

Depending on the metallurgical properties of the material and/or the desired mechanical properties of the welded part, the preheat and interpass temperatures may be evaluated for different reasons. For example, a procedure for welding mild steels, which have low carbon content and relatively low hardenability and are used in an application without special maintenance requirements, may consider minimum preheat and interpass temperatures based on material thickness.

Welding procedures used for heat treatable low-alloy steels and chrome-molybdenum steels with shock requirements will normally specify a minimum and maximum value for preheat and interpass temperatures. These low-alloy materials can have high hardenability and are prone to hydrogen cracking.

Allowing these materials to cool or overheat too quickly can significantly degrade their properties. When welding nickel alloys, the high heat input during welding is primarily a concern. The heat input from the welding process and the preheat and interpass temperatures can seriously degrade these materials. High heat input can lead to excessive liquation, carbide deposition and other harmful metallurgical phenomena. These metallurgical changes can cause cracking or loss of corrosion resistance.

Welding procedures for some aluminum alloys often involve the overall reduction in heat input. For these materials, the maximum preheat and interpass temperatures are controlled to minimize the influence of annealing and aging on the heat-affected zone (HAZ) and the resulting loss of tensile strength.

In critical applications, the preheat temperature must be precisely controlled. In these situations, adjustable heating systems are used and thermocouples are attached to monitor the part being heated. These thermocouples provide a signal to the controller that can control the power source required for heating. Using this type of equipment, the part being heated can be controlled to extremely tight tolerances.

Why is preheating necessary?

Some of the main reasons for preheating are..

- To expel moisture from the weld area: This usually involves heating the surface of the material to a relatively low temperature, just above the boiling point of water. This dries the sheet surface and removes the unwanted contaminants that might otherwise cause porosity, hydrogen embrittlement or cracking due to the absorption of hydrogen during the welding process.

- To reduce the temperature gradient: All arc welding processes use a high-temperature heat Reference(s). A strong temperature difference occurs between the local heat source and the cold base material being welded. This temperature difference causes differential thermal expansion and contraction and high stresses around the welded area. Reducing the temperature difference by preheating the base material minimizes problems with distortion and excessive residual stress. If no preheating is done, there can be a large temperature difference between the weld site and the parent material. This can cause rapid cooling, which in turn leads to the formation of martensite and likely cracking when welding some high-hardness materials.

Heat treatment after welding

Different types of post-weld heat treatments are used for different reasons and with different materials..

- Stress reduction - Heat treatment after welding is usually used to reduce stress. The purpose of stress reduction is to remove any internal or residual stresses that may be present during welding. Stress reduction after welding may be necessary to reduce the risk of brittle fracture, prevent subsequent deformation during machining, or eliminate the risk of stress corrosion cracking.

- Obtaining a suitable metallurgical structure - Some alloy steels may require a thermal tempering treatment to obtain a suitable metallurgical structure. This treatment is carried out after the weld has cooled, but under certain conditions this treatment may need to be carried out before the weld has cooled to prevent cracking.

- Normalizing after welding - Extremely coarse steel weld structures, such as with the electroslag welding process, can be normalized after welding. This treatment refines the coarse grain structure, reduces post-weld stresses and removes any hard areas in the heat-affected zone.

- Restoration of original properties - Precipitation hardening alloys, such as heat-treatable aluminum alloys, sometimes require post-weld heat treatment to restore their original properties. In some cases, only aging treatment is used, although full heat treatment and artificial aging treatment will result in better recovery of properties after welding.

- When pre-heating and/or post-weld heat treatment are used in welding, it is important that the welding inspector understands these requirements to ensure that they are performed correctly and in accordance with the relevant welding procedure specifications and/or requirements in the standard.

Related Post(s)

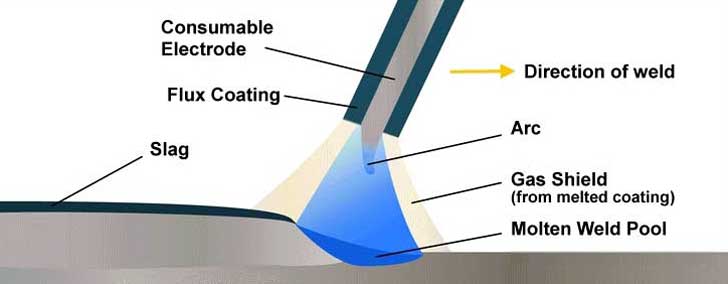

SMAW electrode welding uses an electric current to form an arc at the end of a consumable electrode....