Time of Flight Diffraction (TOFD) |

Time of flight diffraction (ToFD) is a reliable method of ultrasonic testing that is a highly sensitive and accurate method for non-destructive testing.

It is mainly used for rapid testing of circumferential and axial welds, which is called perpendicular ToFD scanning. It can also be used for weld overlays and inspection of the heated parts of other components such as pipelines, clad material, pressure vessels, storage tanks and structural steels.

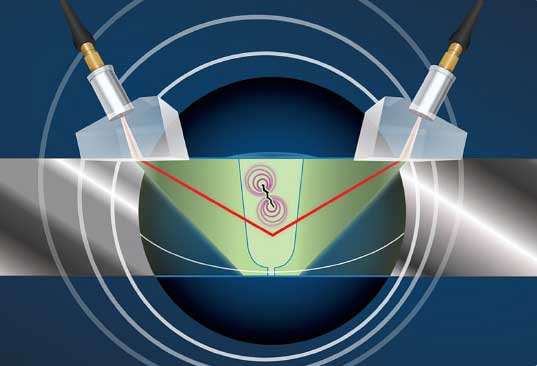

As with other forms of ultrasonic testing (UT), two probes are placed on either side of a weld. One of the probes emits an ultrasonic pulse that is picked up by the probe on the other side.

In undamaged tubes, the signals captured by the receiver probes come from two waves: one running along the surface and one reflecting off the far wall. When a crack is present, there is diffraction of the ultrasonic wave from the tip(s) of the crack. Using the measured escape time of the pulse, the depth of a crack tip can be automatically calculated by simple trigonometry.

Image..

www.james-fisher.com

Image..

www.james-fisher.com Advantages of ToFD

Flight diffraction is generally considered one of the fastest NDT methods. One of its main advantages is the ability to find multiple defects, even of different types, and assess their extent in a short period of time. ToFD can identify damage that is normally only visible through other methods such as radiography.

Image..

www.acuren.com

Image..

www.acuren.com Because ToFD is based on diffraction, it is relatively independent of the angle of the weld and the orientation of any defects. It uses the time of arrival signals reflected from crack tips to accurately determine the position and size of the defect. A single beam can cover a large area and the entire process is quick to set up and use. The procedure is highly sensitive to all types of weld defects and can be used for corrosion inspections.

Related Post(s)

IRIS is a technique that can be applied on both ferrous and non- ferrous materials and even on non-conductive materials...

Eddy current array (ECA) is a nondestructive testing technology that provides the ability to electronically drive multiple eddy current...