Vacuum box testing |

The vacuum box test is a non-destructive examination used to detect weld seam leaks. A vacuum box and compressor create a high or low pressure vacuum while a detergent solution is applied to the test area. The detergent bubbles, revealing leaks within the pressure range created. This test method is suitable for leak detection on pipes, containers and sheet metal structures.

99% of all welds seams can be tested for leaks with this system.

The purpose of the vacuum box technique of bubble leak testing is to detect leaks in a pressure boundary that cannot be directly pressurized. of the boundary, causing bubbles to form as leak gas flows through the solution.

Inspection capabilities with Vacuum box tests

- Lap welding, butt welding and jacket-ring welding

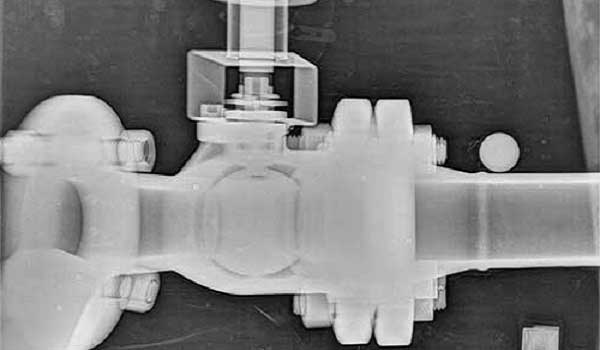

- Piping systems and pressure vessels

- Tank bottoms

- ERW seam in pipelines

- Objects on which a pressure differential can be created over the area to be examined

How the method works?

Vacuum box tests can detect leaks through the thickness and are commonly used for testing welds. Cracks, pores and lack of fusion are typical causes of leaks that can be detected by this method. A bubble-forming solution is applied to the surface to be tested by flowing, spraying or brushing the solution over the examination area.

Household soap or detergents specifically intended for cleaning are not allowed as substitutes for bubble-forming solutions. A commercial leak detection solution compatible with the temperature conditions during the test shall be used. As a standard technique, the temperature of the surface of the part being examined shall be no lower than 5°C (40°F) and no higher than 50°C (125°F) during the examination.

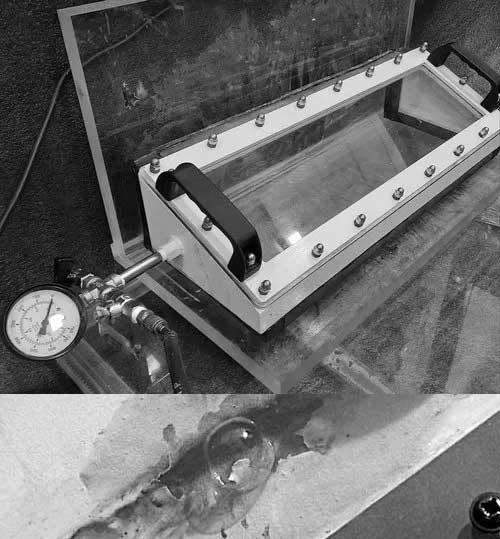

A vacuum box is then placed over the surface with a viewing window large enough to view the entire area and to let in sufficient light for proper examination. The box, which can produce and hold a pressure differential of at least 0.55 bar (8 psi) due to its construction and a suitable gasket, is then evacuated.

A calibrated pressure gauge is placed in the system to verify the required differential pressure to detect vacuum sealing or other types of leaks in the equipment. The area is then viewed for evidence of leaks through thickness by the formation of bubbles on the surface.

Advantages

- Provides an immediate indication visual of the location of any leaks present

- Can detect small leaks within a given area

- Size and orientation of any leaks will have to be analyzed with a secondary NDT method

- For standard testing surface temperature of the test material must be between 5°C and 50°C. Otherwise, a procedure effective at the temperature range must be demonstrated.

Related Post(s)

OSI can be applied for the production of overview images (the so-called shadow images) for the detection of installations or add-ons in...

Eddy current array (ECA) is a nondestructive testing technology that provides the ability to electronically drive multiple eddy current...