|

Exposure to hydrogen sulfide (H2S) in the oil and gas industry |

On Oct. 26, 2019, an employee and his wife were both fatally injured as a result of hydrogen sulfide (H2S) at a water overflow station in Odessa, Texas - one of six fatal H2S accidents in the United States in the past two years. On May 4, 2021, the U.S. Chemical and Hazard Investigation Board (CSB) published its final report of the incident with guidance on how to prevent future incidents with appropriate safety measures.

This article describes what happened, why H2S safety is critical to the oil and gas industry and the latest guidelines to prevent H2S injuries and deaths.

What happened?

The CSB report states that the pumper in question arrived at the water filling station in response to an oil level alarm on a pump at the facility. A water filling station common in Texas uses pumps in pump housings to inject water into the oil reservoir to increase pressure. The water is later removed from the extracted oil; however, the water removed in this process may contain harmful contaminants, such as H2S gas. H2S is extremely toxic and can quickly become deadly when high concentrations accumulate in a confined space such as a pump station.

On the evening of Oct. 26, the employee entered the pump house and then closed two valves in an attempt to isolate the alarming pump. He was not wearing a personal monitoring device and did not perform a lockout to isolate the pump from power source before performing the work - critical steps that potentially could have saved his life. Additional risk factors included poor site security and a non-functioning H2S detection and alarm system in the pump house.

At some point, before or after the worker's arrival, the pump automatically turned on, releasing H2S gas into the pump housing. The enclosed space was not adequately ventilated, and the gas quickly concentrated to lethal levels, fatally injuring the pump attendant. Later that evening, his wife, concerned that her husband had not come home, drove to the construction site with their two children. She too entered the pump house and was fatally injured by the toxic gas. The children in the vehicle were unharmed.

Why is H2S so dangerous?

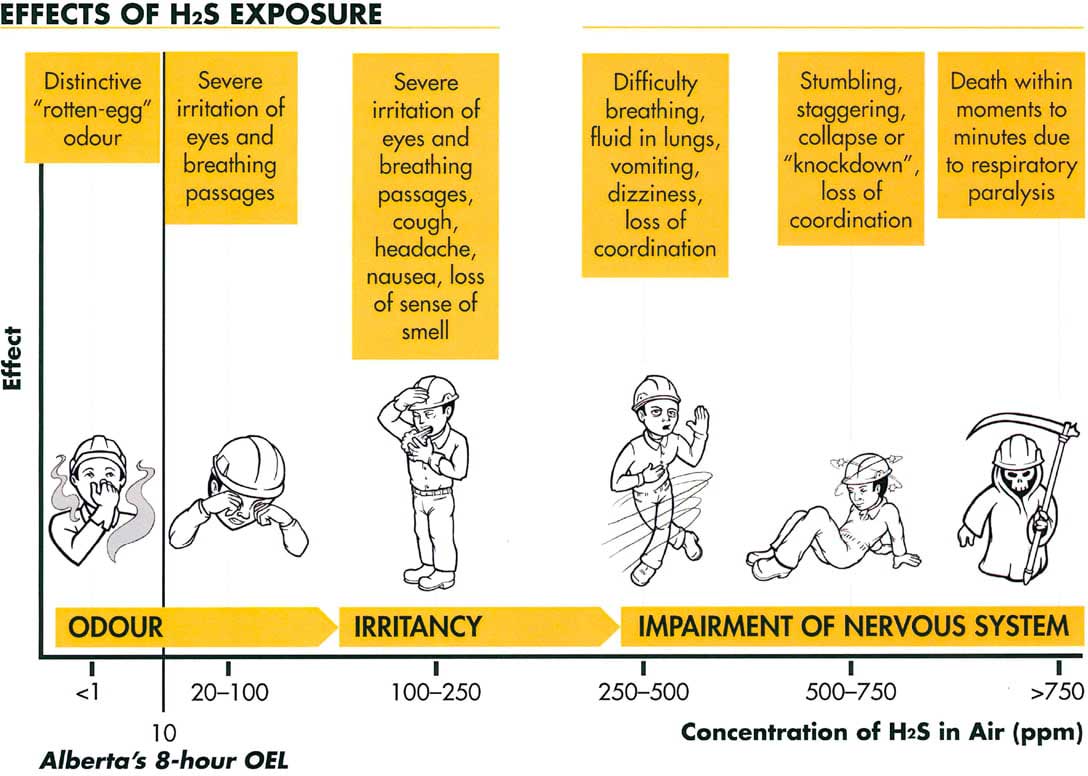

Hydrogen sulfide (H2S ) is common in oil and gas operations, and is extremely deadly. H2S gas is heavier than air, so it accumulates quickly in low-lying areas, as well as in confined, poorly ventilated spaces such as the pump house at the October 2019 incident. While H2S gas can be dangerous even at low concentrations, just a few breaths at high concentrations can lead to unconsciousness, coma and even death.

Hydrogen sulfide is one of the leading causes of workplace gas inhalation deaths in the United States. According to the Bureau of Labor Statistics (BLS), hydrogen sulfide caused 60 worker deaths between 2001 and 2010. In the past 2 years alone, there were 6 fatalities in the United States.

Although H2S gas produces recognizable 'rotten eggs' odor, it is very risky to rely on odor to avoid exposure to injury or death. This is because H2S gas disables the human sense of smell fairly quickly (olfactory desensitization). In fact, high levels of H2S gas will turn off the sense of smell almost immediately, making smell extremely unreliable for identifying the presence of H2S gas or recognizing increasing levels of H2S.

Because smell is unreliable, it is imperative to install reliable gas detectors and environmental monitors in any room where there is a risk of H2S gas. This is similar to the need for carbon monoxide sensors in a home. Workers should also always wear personal gas monitoring devices to ensure that their breathing zone is safe from H2S. These devices continuously monitor the air the user breathes and immediately alert them to the presence of H2S gas in their environment so they can evacuate and move to safety and avoid the harmful effects of prolonged exposure to H2S.

As with any critical safety issue, gas detection is essential to adequately protect the health and safety of workers and prevent fatal accidents. Multiple lines of defense, including overlapping layers of gas detection and monitoring, are necessary to mitigate the high risk level of exposure to H2S.

Image..

https://hnhu.org

Image..

https://hnhu.org

Preventing H2S incidents: CSB Guidelines

As a result of their investigation, the CSB, the U.S. Chemical Safety and Hazard Investigation Board, made several recommendations to address the risks of exposure to H2S and prevent future incidents. These recommendations are..

Require the use of personal H2S detection equipment.

Develop a site-specific, formalized, and comprehensive lockout/tagout program for each facility.

Commission a comprehensive, independent analysis of each facility to examine ventilation and mitigation systems.

Develop and demonstrate the use of a safety management program that emphasizes the protection of employees and non-employees from H2S.

Ensure that H2S detection and alarm systems are properly maintained and configured and develop site-specific detection and alarm programs and procedures.

Ensure that H2S detection and alarm systems utilize multiple alarm layers unique to H2S.

Develop and implement a formal, written, site-specific security program to prevent the unknown and unplanned access of non-employees.

Related Post(s)

Carbon monoxide is often referred to as a silent killer. It is a leading cause of poisoning related deaths and illnesses worldwide...