|

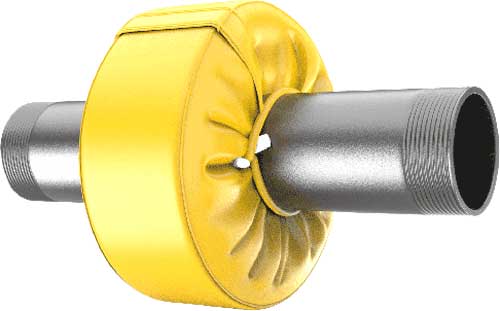

Flange Guards |

Flange Guards (or Safety splash guards) are designed to contain and detect hazardous splashes. They are used to prevent injury to personnel or damage to equipment in the event of a leak or spill of acids, alkalis, chlorine and other hazardous liquids at pipeline connections (such as flanges, valves or expansion joints).

The spray shields are customized to the application and are made of PTFE, polypropylene, PVC, polyethylene and stainless steel. They are available for all ASME, DIN, ISO, BS flange sizes.

Stainless Steel Flange Guard

This simple design lasts longer than any other type/material. Suitable for high pressure and high

temperature applications. Most important is the internal multi-layer steel mesh, which effectively

disperses the released pressure, preventing the formation of mist and fog. Stainless steel safety

shields are recommended for LNG applications.

PTFE Flange Guard

The PTFE shield is made of three layers of woven fiberglass with Teflon coating and a central Teflon

edge for strength. This material is inherently resistant to ultraviolet radiation. A transparent

Teflon window houses a litmus leakage indicator.

PVC Flange Guard

PVC is resistant to most common acids, salts and alkalis, and they are dielectrically constant.

PVC or Poly Vinyl Chloride has a chlorine content that makes flange shields fire retardant. These

shields also come in a transparent material that makes visual inspection of flanges very easy.

Flange guards are the last line of defense. They are not designed to contain the leak indefinitely, but to prevent harmful spray that causes fires or explosions, resulting in significant plant downtime, capital expenditures and even loss of life.

Related Post(s)

The acetylene cylinder is an exception to other gas cylinders, because it is completely filled with a porous mass, in which acetone has been sucked up...