|

G-Range Pipe Connectors in High Pressure Applications |

What are G-Range pipe connectors?

Due to their efficiency, lightness and reliability, together with extreme qualities of leak tightness, the G-Range pipe connection offers significant benefits for use in industrial plant in a wide variety of applications. Although designed primarily for adverse pressure and temperature conditions, more modest applications can be considered due to ease of installation and assembly, particularly when compared with the alignment and tightening of standard flanges.

The G-Range pipe connections are available in all material grades required by Norsok M630 and Statoil TR2000 from Norsok M650 qualified manufactures. It was one of the connections originally approved by Statoil when they did the interchangeability test in 1996.

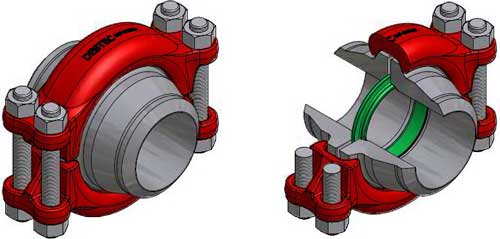

The G-Range pipe connection comprises.. a pair of hubs for welding to the pipe (similar to a flange); a clamp set, which can be rotated around the hubs to suit the most practical positions; and a seal ring.

The seal ring is a modified cone ring giving excellent leak tightness properties under the most severe conditions of pressure and/or thermal shock.

On assembly the taper joint faces compress the seal ring radially. The sealing force is provided by the stored energy in the stressed seal ring, any internal pressure intensifies the sealing action.

High Pressure Containment

The higher the pressure, the more effective the G-Range connection becomes, as internal pressure

intensifies the seal.

High Temperatures

The standard all-metal seal ring is suitable for most applications - maximum temperatures are limited

only by the connection materials selected.

Extreme Leak Tightness

The seals remain leak tight under the most arduous conditions of pressure, temperature and vacuum

conditions, even after many thousand hours of operation.

Resistance to Pressure and Thermal Shock

Cold quench conditions and thermal cycling are the cause of most leakage problems, where conventional

compressible type joints and seal materials are used. The flexibility of the seal ring compensates

for this during thermal transient conditions.

Materials

Destec G-Range connections are supplied in these standard materials. Destec Seal Rings are supplied

coated with either PTFE, Molybdenum Disulphide or Graphite, depending on the application. Special

G-Range connections are manufactured in many materials including Duplex steels and Nickel-based

alloys.

Re-Usable Seal Rings

The 'all-metal' seal ring is elastic in design, and, on dismantling, reverts to its original form,

ready for re-use. All seals of given size are interchangeable without any pre-fitting.

Special Connections

Existing troublesome flange joints can usually be converted on site to incorporate the seal ring,

as can vessel and heat exchanger closures. Seal rings are currently in use up to 2m diameter (2000mm).

Welding of Hubs to Pipe Ends

The standard hub is provided with a weld preparation for welding from outside only. Protect the

hub seat with the metal guards provided, and against oxidation. If hubs welded to pipe lengths

are not to be assembled immediately, remove the metal guards and coat hubs with grease or lanolin

preservative. Replace metal guard for storage.

Reference(s) ..March 9, 2014...www.norwayexports.no and www.destec.co.uk

Related Post(s)

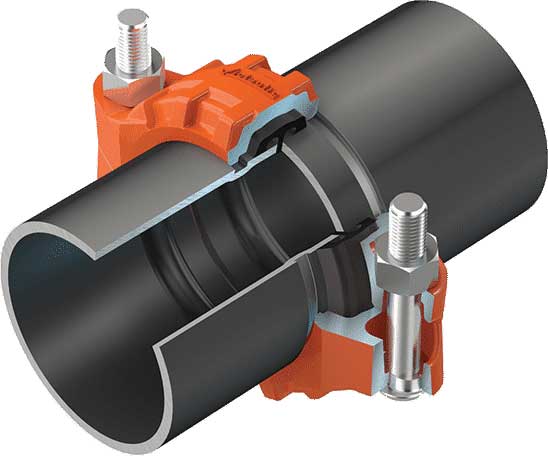

Victaulic provides products for Fire Protection, Data Centers, Shipbuilding, Commercial Buildings, Mining, BioFuels, and Industrial Manufacturing...