Compression Fittings

Compression fittings are one of the most common and versatile methods of joining

small diameter metal or hard plastic tubing

Particularly useful due to their extreme temperature and pressure capabilities, and their compatibility

with aggressive fluids.

Compression fittings are used in various industries, such as petrochemicals, laboratories, aerospace, shipbuilding, heavy industries etc. and they are used to make leak-free pipe connections relatively easily and quickly. Swagelok and Parker are the two leading manufacturers in the compression fittings market.

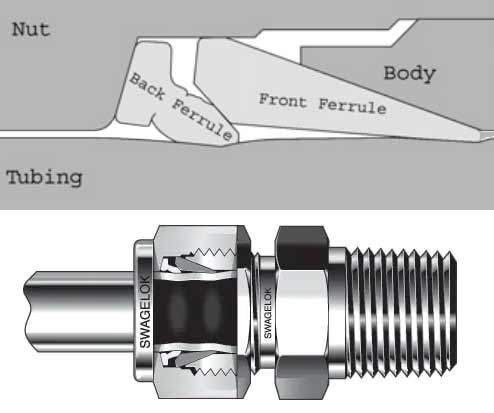

Compression fittings vary in design from manufacturer to manufacturer, but all consist of the same three basic elements: a compression nut or screw, one or more compression rings (ferrules) and a compression fitting housing.

Example: Double ferrule compression fitting

The operating principle is as follows: the tube is inserted into the end of the fitting and the nut is tightened, forcing the ferrules into the fitting housing.

Image..swagelok.com

Image..swagelok.com As the ferrules are pushed axially into the fitting housing, the angular shape of the housing presses the end of the ferrules radially onto the outside diameter of the tube, and a leak-free connection is guaranteed.

The video below shows a practical example of how to make a compression connection

Image..swagelok.com

Image..swagelok.com Ferrules

The ferrule is the main sealing component of a compression fitting, and is manufactured in a wide range of material grades, from stainless steel to graphite.

Most commonly used ferrules, however, are made of metal. Metal ferrules are suitable for a wide temperature range, and can withstand high pressure loads, without relaxation.

One-piece vs. two-piece ferrules

Most basic compression fittings have a single ferrule. Single ferrule designs minimize the total number of components and work reliably when manufacturing softer materials (plastic or brass, for example).

With harder materials such as steel, however, torque is often transferred from the compression nut to the ferrule when the nut is tightened. The resulting rotation can cause the ferrule to compress asymmetrically or shift over time due to residual torque.

With stainless steel, rotation of the ferrule can also lead to wear and permanent leakage. Adding an additional, freely rotating rear ferrule can disconnect the nut from the front ferrule, preventing torque transfer.

Tubing

Compression fittings are most often used with "hard" grade tubing because the tubing wall must be rigid enough to withstand the compression forces applied by the ferule. Common choices are metal tubing (such as stainless steel or copper) and rigid plastic tubing (such as PEEK, nylon, Teflon®, Kynar® or polyethylene).

Some types of compression fittings

Union Straight & Red.

Male Connector

Female Connector

Long Reducer

Cap & Plug

90deg Elbow

90deg Elbow (Male)

Tee Union & Reducing

Tee (Male)

The images (Swagelok) above show commonly used compression fittings. However, many more types are available. In brochures from Swagelok and Parker, for example, you will find many more types.

You can also find dozens of videos on YouTube from e.g. Swagelok, which can tell you even more than this page displays.

Conclusion

Compression fittings are widely used in a number of industries, and can be an asset in almost any fluid power design. The biggest advantage is the ability to make connections to both metal tubes and also hard plastic tubes.

In addition, compression fittings are suitable for high pressure and high temperatures, they are corrosion resistant and most importantly, the ease with which a connection can be made.

Related Post(s)

Process instruments are essential components of any oil and gas operation and are used to measure and monitor various aspects of the production process...