What are leak repair clamps?

Leaks can cost companies millions of dollars in lost energy, while increasing emissions, creating safety risks and decreasing operational reliability. With a repair clamp, a leak can be fixed without interrupting normal business operations. The methods are non-destructive, preserving equipment integrity and longevity.

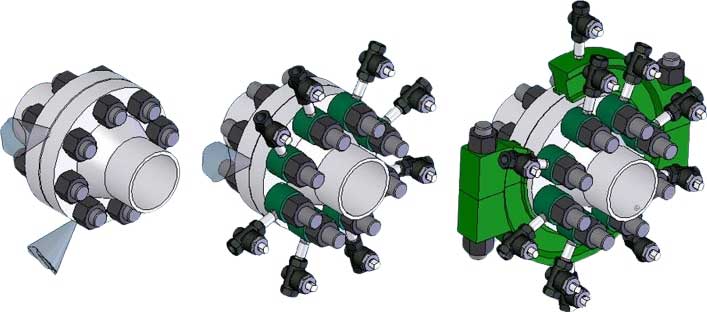

This article describes the repair clamps which are specially fabricated after the clamp has been measured on site and the customer has approved the calculations and dimensions. The clamp size can vary from 1/2in to ...in, and can withstand high pressure up to 340bar and temperatures up to 800°C.

Custom clamps are also available. These are usually only suitable for straight lengths of pipe, and not suitable for high pressures and temperatures. In practice, these versions are also called maintenance clamps, and have confirmed their service more than once.

Image..

www.viadux.com.au

Image..

www.viadux.com.au Specially manufactured leak repair clamps

First of all... most suppliers of these clamps call it an "Enclosure", and this page will frequently use that term.

Depending on the size of pipes, flanges, fittings, valves, etc., enclosures are designed in two or more sections. The thickness of the enclosures varies according to the maximum fluid pressure and maximum operating temperature.

On the inside of an enclosure, a groove is machined on the left and right sides. A copper tube, for example, is inserted into this groove. During installation of the clamp, the copper tube is compressed, sealing the leak almost one hundred percent.

On the outside of an enclosure, so-called injection valves are installed during fabrication. Through these valves, special compound is injected into an installed clamp, which ensures a one hundred percent seal. Depending on the design, injection valves are possible in all areas of the enclosure. It is usually necessary to re-inject the enclosure after a few days or weeks.

Back clamp

When the leak is at the weld, the pipe or the fitting is almost completely cracked, further degradation

and potential disconnection over time is possible. By designing a strong back clamp,

connected to the enclosure itself or separately, that problem can be remedied.

Gaskets of flat flanges

For a leak on the gasket of flat flanges, the seal is obtained by injecting a clamp with a central

groove and by installing and injecting ring adapters on all bolts.

Valve Stuffing Boxes

A leak in a stuffing box is usually treated with a G-clamp placed around the stuffing box. A drill

is then used to drill through the G-clamp to the gasket. This ''breakthrough'' method creates a

channel for injecting the sealing compound.

All text under any image of this page marked with an asterisk are the property of Leaksealing.Com and have been modified to match the style of this website

Remark(s) of the Author...

LEAK REPAIR

With this page, I have tried to explain what custom leak repair clamps are, and what configurations are possible. In practice, however, there are many more solutions which I cannot explain here all.

- Before an enclosure is installed, it is desirable, that the system that is being worked on is temporarily depressurized, and a ambient temperature can be maintained.

- Also, the leak should first be wrapped with thin sheet, otherwise the compound may enter the product.

*

Pipe wrapped with thin sheet

*

Pipe wrapped with thin sheet

Working on in-service systems is and remains a high-risk job. Therefore, it is very important that only qualified personnel in leak sealing perform the work. It should also be expected that the client and the executing party work closely together and actually honor agreements made in advance.

And there's something each of us can do to make sure we all go home as whole as when we started the day. One step at a time, we can make our workplaces better places to work.

Related Post(s)

Shell has successfully installed the first 3D printed leak repair clamp in service...