|

Emergency Shutdown Valves |

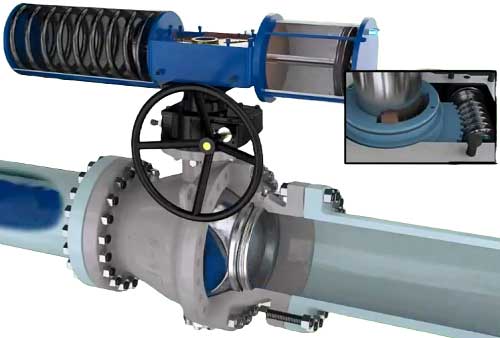

Emergency Shutdown Valves (ESV) or (ESDV) are widely used in critical units in oil, gas and chemical processing plants and refers to an actuated valve. Various valve types can be used for an ESV, but the most common is the Ball valve.

The Emergency Shutdown Valve, ESV, acts as a safeguard against exceeding the set pressure. During normal operation, the valve remains open for extended periods of time, months or even years.

In case the set point is exceeded or the power or signal is lost the ESV closes during partial or complete process shutdown of the system against which the valve protects. As a rule of thumb for the closing time is 1 second for a 1 inch valve size, so 6 seconds for a 6 inch valve; however, there are also ESV's that close much faster.

How ESV works?

Full Open Position – Normal Operation

The ESV ensures a minimal pressure difference when the valve is fully open. The full bore ball valve

acts like a pipe, reducing the turbulence of the process fluid.

Full Closed Position – Emergency Situation

The set point pressure has been exceeded and the ESV is fully closed, providing an airtight seal

with its double seat design.

Unlocking guaranteed by position indicator

Once the pressure has been brought to a safe level, the device can be opened by..

- Manual reset

- Low setpoint reached

- Restore power

The ESV is equipped with an easy-to-read position indicator on the actuator, which helps confirm that the valve is locked in the fully open position.

Emergency Shutdown Valve - type Ball

An ESV must act quickly to minimize the effect of a hazardous operating condition. The design of the quarter-turn ball valve provides inherently fast operation. In addition, with its equal percentage flow characteristic (high gain), it can not only close quickly, but also greatly reduce the amount of process fluid passing through it.

For shutdown valves used in safety instrumented systems, it is essential to know that the valve is capable of providing the required level of safety performance and that the valve will operate on demand.

The required level of performance is determined by the Safety Integrity Level (SIL). To meet this level of performance, it is necessary to test the valve.

Shutdown Valve (SDV) vs Emergency Shutdown Valve (ESV)

The construction and accessories of Shutdown Valves (SDV) and Emergency Shutdown Valve (ESV) are similar.

What is the basis for distinguishing their name?

- Shutdown valve refers to activated valve that closes during partial or complete process shutdown of the system against which the valve protects.

- Emergency shutdown valve is an actuated valve that closes when activated by a signal from an level indicator during an emergency situation.

Emergency shutdown valves are usually located in the incoming line and outgoing line of the plant or platform.

Note that some projects do not use the term "ESV" for tag numbering, instead the term "SDV" is used for closing a valve that ignores their services. In this case, the trip logic diagram indicates which activated valve acts as an emergency stop valve.

References..

www.valmet.com

instrumentationtools.com

www.chemengonline.com

Image

animation..pamaker@163.com

Image

animation..pamaker@163.com