Steam.. The energy fluid

Steam has come a long way from its traditional associations with locomotives and the Industrial Revolution. Steam today is an integral and essential part of modern technology. Without it, our food, textile, chemical, medical, power, heating and transport industries could not exist or perform as they do.

Steam provides a means of transporting controllable amounts of energy from a central, automated boiler house, where it can be efficiently and economically generated, to the point of use. Therefore as steam moves around a plant it can equally be considered to be the transport and provision of energy.

For many reasons, steam is one of the most widely used commodities for conveying heat energy. Its use is popular throughout industry for a broad range of tasks from mechanical power production to space heating and process applications.

Steam is efficient and economic to generate

Water is plentiful and inexpensive. It is non-hazardous to health and environmentally sound. In its gaseous form, it is a safe and efficient energy carrier. Steam can hold five or six times as much potential energy as an equivalent mass of water.

When water is heated in a boiler, it begins to absorb energy. Depending on the pressure in the boiler, the water will evaporate at a certain temperature to form steam. The steam contains a large quantity of stored energy which will eventually be transferred to the process or the space to be heated.

It can be generated at high pressures to give high steam temperatures. The higher the pressure, the higher the temperature. More heat energy is contained within high temperature steam so its potential to do work is greater.

- Modern shell boilers are compact and efficient in their design, using multiple passes and efficient burner technology to transfer a very high proportion of the energy contained in the fuel to the water, with minimum emissions.

- The boiler fuel may be chosen from a variety of options, including combustible waste, which makes the steam boiler an environmentally sound option amongst the choices available for providing heat. Centralised boiler plant can take advantage of low interruptible gas tariffs, because any suitable standby fuel can be stored for use when the gas supply is interrupted.

- Highly effective heat recovery systems can virtually eliminate blowdown costs, return valuable condensate to the boiler house and add to the overall efficiency of the steam and condensate loop.

The increasing popularity of Combined Heat and Power (CHP) systems demonstrates the high regard for steam systems in today's environment and energy-conscious industries.

Reliable under High Loads

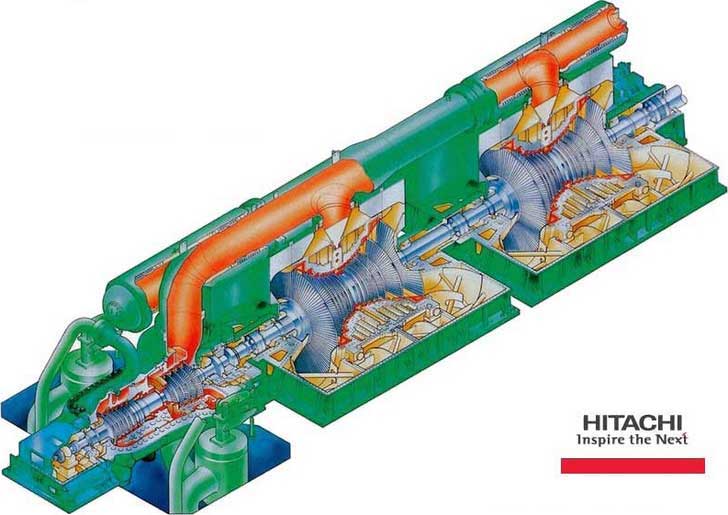

The blade tips of a turbine rotate some 3,000 times a minute and are thus faster than the speed of sound. The blades under extremely high steam temperatures (approx. 620 °C) and pressures (up to 250 bar) are subjected to extreme loads and stresses. Even so, it is expected of steam turbines that they are reliable and perform their work round the clock.

Steam can easily and cost effectively be distributed to the point of use

Steam is one of the most widely used media to convey heat over distances. Because steam flows in response to the pressure drop along the line, expensive circulating pumps are not needed.

Due to the high heat content of steam, only relatively small bore pipework is required to distribute the steam at high pressure. The pressure is then reduced at the point of use, if necessary. This arrangement makes installation easier and less expensive than for some other Heat Transfer fluids.

Overall, the lower capital and running costs of steam generation, distribution and condensate return systems mean that many users choose to install new steam systems in preference to other energy media, such as gas fired, hot water, electric and thermal oil systems.

Steam is easy to control

Because of the direct relationship between the pressure and temperature of saturated steam, the amount of energy input to the process is easy to control, simply by controlling the saturated steam pressure. Modern steam controls are designed to respond very rapidly to process changes.

Typical Control Valve

Typical Control ValveThe image above shows a typical control Valve and pneumatic actuator assembly, designed for use on steam. Its accuracy is enhanced by the use of a pneumatic valve positioner.

The use of two-port Valves, rather than the three-port Valves often necessary in liquid systems, simplifies control and installation, and may reduce equipment costs.

Energy is easily transferred to the process

Steam provides excellent Heat Transfer. When the steam reaches the plant, the condensation process efficiently transfers the heat to the product being heated.

Steam can surround or be injected into the product being heated. It can fill any space at a uniform temperature and will supply heat by condensing at a constant temperature; this eliminates temperature gradients which may be found along any Heat Transfer surface - a problem which is so often a feature of high temperature oils or hot water heating, and may result in quality problems, such as distortion of materials being dried.

Because the Heat Transfer properties of steam are so high, the required Heat Transfer area is relatively small. This enables the use of more compact plant, which is easier to install and takes up less space in the plant. A modern packaged unit for steam heated hot water, rated to 1200 kW and incorporating a steam plate Heat Exchanger and all the controls, requires only 0.7 m2 floor space. In comparison, a packaged unit incorporating a shell and tube Heat Exchanger would typically cover an area of two to three times that size.

The modern steam plant is easy to manage

With proper maintenance a steam plant will last for many years, and the condition of many aspects of the system is easy to monitor on an automatic basis. When compared with other systems, the planned management and monitoring of steam traps is easy to achieve with a trap monitoring system, where any leaks or blockages are automatically pinpointed and immediately brought to the attention of the engineer.

This can be contrasted with the costly equipment required for gas leak monitoring, or the time-consuming manual monitoring associated with oil or water systems.

Reference(s) (partially) for this page.. Spirax Sarco