|

Heat Exchangers Shell & Tube |

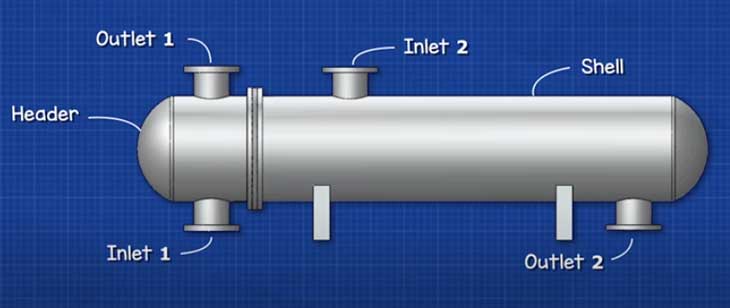

Basic construction of shell and tube Heat Exchangers

Shell and tube Heat Exchangers represent the most widely used vehicle for the transfer of heat in industrial process applications. They are frequently selected for such duties as..

- Process liquid or gas cooling

- Process or refrigerant vapor or steam condensing

- Process liquid, steam or refrigerant evaporation

- Process heat removal and preheating of feed water

- Thermal energy conservation efforts, heat recovery

- Compressor, turbine and engine cooling, oil and jacket water

- Hydraulic and lube oil cooling

- Many other industrial applications

Shell and tube Heat Exchangers have the ability to transfer large amounts of heat in relatively

low cost, servicable designs. They can provide large amounts of effective tube surface while minimizing

the requirements of floor space, liquid volume and weight.

Shell and tube exchangers are available in a wide range of sizes. They have been used in industry

for over 150 years, so the thermal technologies and manufacturing methods are well defined and applied

by modern competitive manufacturers.

Tube surfaces from standard to exotic metals with plain or enhanced surface characteristics are

widely available. They can help provide the least costly mechanical design for the flows, liquids

and temperatures involved.

Fixed Tube Sheet, 2-Pass Heat Exchanger

There are two distinct types of shell and tube Heat Exchangers, based in part on shell diameter. Designs from 2" to around 12" in shell diameter are available that feature shell constructions of low cost welded steel, brazed pipe with hub forgings, cast end Bonnets and copper tubing rolled or brazed to the tube sheet. Models of this type generally use1/4" and 3/8" tubing and are frequently 2 or 4 pass for general industrial use.

The other major type of shell and tube Heat Exchanger generally is seen in shell diameters from

10" to over 100". Commonly available steel pipe is generally used up to 24" in diameter.

Above 24", manufactures use rolled and welded steel plate, which is more costly and roundness

can become an issue.

Heat Exchangers of this type are commonly manufactured to the standards set forth by TEMA, the Tubular

Exchangers Manufacturers Association. TEMA, in cooperation with users and manufacturers, establishes

a common set of guidelines for the construction methods, tolerances and practices to be employed.

This allows industrial consumers to obtain more than one manufacturers offerings and know that they

are generally of similar design and construction. Additionally, it allows manufactures to establish

industry approved designs and offer state of the art equipment that help to assure competitiveness

and overall product reliability.

Although there exists a wide variety of designs and materials available, there are components

common to all designs. Tubes are mechanically attached to tube sheets, which are contained inside

a shell with ports for inlet and outlet fluid or gas.

They are designed to prevent liquid flowing inside the tubes to mix with the fluid outside the tubes.

Tube sheets can be fixed to the shell or allowed to expand and contract with thermal stresses by

have one tube sheet float inside the shell or by using an expansion bellows in the shell. This design

can also allow pulling the entire tube bundle assembly from the shell to clean the shell circuit

of the exchanger.

Shell and Tube Heat Exchanger basics explained

Other Pages about Heat Exchangers

Related Post(s)

The floating-head heat exchanger is a type of tube heat exchanger in which the tube sheet combination is independent and can move freely within the shell...