Pipe and Tube Bending

Tube bending methods are mainly classified into two types - hot tube bending and cold tube bending

Hot Tube Bending

As the name suggests, hot tube bending involves heating the tube at a high temperature so the bending process becomes easier. Metals at high temperatures become softer and flexible, so they don’t break and can bend with a lesser force.

A major drawback of this method is that metals expand on heating, so the final dimensions of the bend and the angle of bend can be different on cooling than what is required.

Cold Tube Bending

The cold tube bending method does not require heating the metal tubing to a high temperature, the bending is accomplished at the room temperature of the tube. The major benefit of this method is that it provides higher accuracy, since there is no change in the final dimensions of the metal due to temperature changes.

Besides this temperature-based classification of tube bending processes, the different types of tube bending can also be defined based on the technology used. Below a brief overview of these different types.

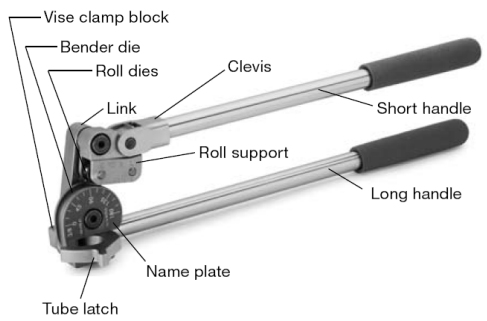

Manual

pipe bender for bending thin wall tube

Manual

pipe bender for bending thin wall tube

Press or Ram bending: Press bending is one of the simplest bending processes. In press bending, two dies that are inclined at the required bend angle are pressed against a straight pipe to create the bend. While press bending is cheap, it doesn’t work on thick tubes.

Rotary draw bending: Rotary draw bending is one of the best and most commonly used bending processes. In this method, the tube is clamped on its outer diameter and turned around a die called bend die. There are many different versions of rotary draw bending process.

Compression bending: Compression bending is an old-school bending method. In this method, the pipe is clamped at both ends, and pressure is applied at the point where the bend is required.

Roll bending: In roll bending, a series of rollers push the pipe through a coil that is winding at the required bend angle. There are many modifications to this method. Roll bending can be classified further into 3-roll bending and 4-roll bending.

The

workpiece is placed on top of the two lower rolls [1]. An upper roll [2] presses the tube down between

the two rollers. This causes plastic deformation, bending of the workpiece. The rolls are often

shaped to fit the tube diameter to prevent deformation of the cross-section. The tube is then fed

through the process by the driven rolls and bent in this way continuously. To achieve the desired

radius the process is repeated.

The

workpiece is placed on top of the two lower rolls [1]. An upper roll [2] presses the tube down between

the two rollers. This causes plastic deformation, bending of the workpiece. The rolls are often

shaped to fit the tube diameter to prevent deformation of the cross-section. The tube is then fed

through the process by the driven rolls and bent in this way continuously. To achieve the desired

radius the process is repeated. Mandrel bending: Mandrel bending involves inserting a metal bar (called a mandrel) inside the tube during the bending process, so the tube does not collapse.

Wiper dies: Wiper dies are also insertions like mandrel, but they aren’t used inside the tube. They are used at the tangent of the bend die to prevent tube material deformation.

Heat induction bending: Head induction bending involves heating the tube through a coil placed near the tube and then bending it with a pivot die.

Read more at: Induction Bending

Sand packing and hot slab forming: Sand packing involves filling sand in a pipe and heating it in a furnace. Then slab forming takes place, in which the pipe is clamped on a slab and bent with a crane or a winch.

What type of equipment do you need for tube bending?

In order to successfully bend a tube, you need a particular set of equipment.

Tube Benders

The first and foremost equipment that is required for tube bending is the tube bender itself. When you have the pipe bending machines ready, you can accomplish the bending process with this equipment itself. The purpose of the other equipment is to provide assistance and improve bend quality.

Depending on the running force, there can be multiple types of tube benders such as..

Manual Tube Bender

Manual tube benders rely on the physical force of the operator who is bending the tube. These tube benders are cheaper as compared to other alternatives. These have limited application as they cannot bend materials with higher strength or thick-walled pipes.

Electric Tube Bender

These tube benders use an electric servomotor to move the dies and accomplish the bending process. These are a little bit more expensive than manual benders, but they can work on hard pipes very well.

Hydraulic Tube Bender

Hydraulic tubes rely on hydraulic pressure (pressure created by narrow water beams), the same principle that is used in cranes and other high-force machines. These tube benders can bend even the thickest and hardest pipes out there. These can operate with electricity (hydraulic/electric tube benders) or without it.

Die Sets

Most tube bending technology require a set of dies to hold the tube and to apply pressure on them for bending purposes. The main dies used for this purpose are clamp die, bend die, and pressure die. Clamp die are generally stationary, while the pressure die apply force to create the bend.

Mandrels

Pipe bending machines, regardless of how efficient they are, can sometimes result in the collapse of the pipe or the deformation of shape. This is why a bar called a mandrel is inserted into the tube to preserve its integrity.

Wiper Dies

Wiper dies are inserted in the tangent of the bend die, at the point where the bend die touches the tube bend. The aim of wiper dies is to prevent material deformation that occurs during the bending process.

Tube and Pipe Bending Terms

When you are choosing a tube bender or doing the bending process itself, there are certain terms you will frequently encounter.

Wall Thickness

Wall thickness is the thickness of the material of the tube, generally measured in millimeters. Thicker tubes are more sturdy but can be a little harder to bend.

Inside Diameter (ID)

Inside diameter is the diameter of the inside of the tube, measured till the inside edge. If you are using a mandrel, the thickness of the mandrel is decided based on this diameter.

Outside Diameter (OD)

Outer diameter is the diameter of the tube measured till the outside edges. The size of tooling you use is calculated based on this diameter.

Degree of Bend (DOB)

The degree of bend (DOB) is the angle at which the pipe is bent. This angle is generally measured in degrees.

Center Line Radius (CLR)

Centerline radius is a little tricky to understand. By definition, it is the radius of the center of curvature of the bend, the center of the axis of the tube. To understand this, imagine the curved part of the bent tube to be a full circle. The centerline axis will be the radius of the circle.

To calculate CLR, simply trace the bent part of the tube on paper. Using a compass, move the bend along the trace to extend the curve until it’s a full circle. Measure the radius of this circle to the center of the tube, it will be the centerline radius.

The center line radius is inscribed on the tooling you use, to make sure it is the right size for the required bend.

Achieved Center Line Radius (Achieved CLR)

When the tube is bent, the final bend measurements can differ a little bit from the intended, due to little changes and deformations in the metal walls of the tube. The final center line radius is called the achieved center line radius.

Springback

When the bent tube is released from the clamps of tube bender, the tube straightens out a little like a spring released from tension. This change in shape is called springback. For accurate bending, spring back should be as little as possible.

Part source for this page: www.roguefab.com

Related Post(s)

Pipe line freezing is a temporary method of insulating piping systems in which a freeze plug is made in the piping system so that the contents do not have to be drained...