|

What is a Needle Valve Manifold? |

Needle valve manifolds integrate several valves into a common, single housing. They are mounted in control and measurement systems directly in front of pressure gauges or pressure transmitters to protect these instruments from damage.

The inlets of the needle valve manifold are connected to process lines, while the outlets connect measuring instruments. Manipulating the manifold valves makes it possible to perform safe static pressure measurements, isolate a measuring instrument from the process line, vent or release the medium from the instrument line, and calibrate the instrument.

The needle valve manifolds are commonly used with differential pressure transmitters. By measuring the pressure difference at two places in the processing system, the flow rate can be determined, the liquid level can be measured in closed tanks, and pumps and filters can be easily inspected.

The needle valve manifolds are widely used in industrial systems, especially in the chemical and petrochemical industries.

Needle Valve Manifolds are available in many configurations. Most used are the 2 way, 3 way and 5 way valve versions.

- 2 way needle valve manifolds are designed to block and bleed with pressure instrumentation

- 3 way needle valve manifolds are designed to block and equalize pressure with differential pressure instrumentation

- 5 way needle valve manifolds are designed to block, bleed and equalize pressure with differential pressure instrumentation

Explanation of the various needle valve manifolds

2 way needle valve manifold with pressure gauge and braket support

Image is property of Badotherm

An example of the simplest configuration is a 2 way needle valve manifold, with an inlet, a main outlet, and a vent outlet. A pressure gauge is connected to the main outlet, the vent outlet remains free. To check the pressure in the system, open the shut-off valve and the pressure will be directed to the pressure gauge. To release the pressure from the pressure gauge without causing damage, first close the shut-off valve and then open the vent valve, releasing the pressure from the pressure gauge. The needle valve manifold mounted in the process line allows you to measure the pressure in the system at any time, in a safe and easy way.

3 way needle valve manifold

A 3 way needle valve manifold consists of 1 equalizing valve and 2 blocking valves. One blocking valve at the high-pressure side and the other at the low-pressure side. Both valves are open while the equalizing valve is closed during normal operation.

The block valves provide instrument isolation, and the one equalizing valve is designated in green and positioned between the high and low process connections of the pressure instrument to provide equal pressures on both sides.

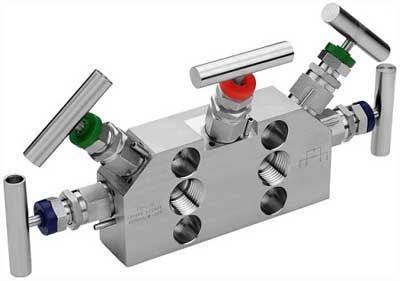

5 way needle valve manifold

A 5 way needle valve manifold consists of 1 equalizing valve, 2 block valves and 2 bleeding valves. One blocking valve at the high-pressure side and the other at the low-pressure side.

The bleed valves are allow venting of trapped pressure through a tube to some remote location.

The one equalizing valve is positioned between the high and low process connections of the pressure instrument to provide equal pressures on both sides. The two block valves are open while the equalizing valve and bleed valves are closed during normal operation.

As described above, there are many possible variations and designs for a needle valve manifolds. Standard valves and manifolds are made of 316 stainless steel, but other exotic materials are also available. The threaded connections are usually 1/4 and 1/2 inch NPT or other common threads, both male and female. Socked weld and butt weld connections are also among the possibilities.

Conformance Standards are..

NACE MR0175 | ISO 15156 | NACE MR0103 | ISO 17495

CRN (Canadian Registration Number) Approved/Registered

ASTM B31.3 Process Piping | ASTM B16.34

MSS-SP-99

References.. www.astava.com & www.badotherm.com