Flange Bolting Torque Table 2A |

The torque tables are built on specific assumptions regarding bolt and nut factor. Before using a given torque table, these assumptions should be verified to insure they are appropriate for the specific application.

Even if all assumptions are appropriate, results may vary depending on actual conditions. Many factors induce scatter in the results or increase the inherent variability in the bolting process. These include variations in the nut factor; bolt, flange and nut condition; equipment calibration and condition; perpendicularity of the bolt, nut and flange; etc.

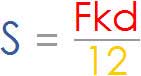

The values in the tables are based on the equation..

|

T = Torque value, (ft-lbs) F = Bolt pre-load, (lbs) k = Nut Factor based on lubricant used d = Nominal bolt diameter, (in.) |

|

The nut factor is not the coefficient of friction.

It is an experimentally derived constant that includes the impact of friction.

ft-lbs to nm = 0.737562149277

nm to ft-lbs = 1.3558179

| Table 2A / Torque FT-LBS - Cold Service ASTM A320 Grade L7 Stud Bolts | |||

| BOLT DIA |

Torque Ft*lb | ||

| 30% Initial Torque |

70% Torque |

100% Final Torque |

|

| 1/2 | 23 | 54 | 76 |

| 9/16 | 33 | 77 | 110 |

| 5/8 | 46 | 107 | 152 |

| 3/4 | 81 | 189 | 270 |

| 7/8 | 131 | 305 | 436 |

| 1 | 196 | 457 | 653 |

| 1.1/8 | 287 | 671 | 958 |

| 1.1/4 | 404 | 943 | 1348 |

| 1.3/8 | 854 | 1279 | 1828 |

| 1.1/2 | 725 | 1689 | 2413 |

| 1.9/16 | 824 | 1922 | 2746 |

| 1.5/8 | 935 | 2183 | 3118 |

| 1.3/4 | 1177 | 2747 | 3924 |

| 1.7/8 | 1461 | 3410 | 4871 |

| 2 | 1792 | 4180 | 5972 |

| 2.1/4 | 2590 | 6044 | 8635 |

| 2.1/2 | 3590 | 8376 | 11966 |

| Table 2A / Torque Nm - Cold Service ASTM A320 Grade L7 Stud Bolts | |||

| BOLT DIA |

Torque N*m | ||

| 30% Initial Torque |

70% Torque |

100% Final Torque |

|

| 1/2 | 31 | 73 | 103 |

| 9/16 | 45 | 104 | 149 |

| 5/8 | 62 | 145 | 206 |

| 3/4 | 110 | 256 | 366 |

| 7/8 | 178 | 414 | 591 |

| 1 | 266 | 620 | 885 |

| 1.1/8 | 389 | 910 | 1299 |

| 1.1/4 | 548 | 1279 | 1828 |

| 1.3/8 | 1158 | 1734 | 2478 |

| 1.1/2 | 983 | 2290 | 3272 |

| 1.9/16 | 1117 | 2606 | 3723 |

| 1.5/8 | 1268 | 2960 | 4227 |

| 1.3/4 | 1596 | 3724 | 5320 |

| 1.7/8 | 1981 | 4623 | 6604 |

| 2 | 2430 | 5667 | 8097 |

| 2.1/4 | 3512 | 8195 | 11707 |

| 2.1/2 | 4867 | 11356 | 16224 |

Notes..

- Bolting torque to develop 70% Bolt Yield Stress at Nut Factor, K=0.16

- This Table is applicable to Never-Seize paste and Fel-Pro lubricant, K=0.16.

- The above Table is applicable only for ASTM A320 Grade L7.

- The torque values are approved for spiral wound graphite and PTFE filled gaskets.

- The Final Torque Value accounts for 10% bolt relaxation.

- This Table is not acceptable for PTFE coated Stud Bolts and nuts, for these refer to Table 5A.

OTHER BOLTING TORQUE TABLES

BOLTING TORQUE TABLE 1 - ASTM A193 AND ASTM A320 GRADE B8, CL2 STUD BOLTS

BOLTING TORQUE TABLE 1A - COLD SERVICE ASTM A193 AND ASTM A320 GRADE B8, CL2 STUD BOLTS

BOLTING TORQUE TABLE 2 - ASTM 193 GRADE B7 AND ASTM 193 GRADE B16 STUD BOLTS

BOLTING TORQUE TABLE 2A - COLD SERVICE ASTM A320 GRADE L7 STUD BOLTS

BOLTING TORQUE TABLE 3 - USE ONLY WITH A193 B8, CL1 BOLTS AT 540°C - 650°C ON UNINSULATED FLANGES

BOLTING TORQUE TABLE 4 - USE ONLY WITH 6061-T6 ALUMINIUM FLANGES

BOLTING TORQUE TABLE 5 - PTFE COATED ASTM A193 B7 and ASTM 193 B16 STUD BOLTS

BOLTING TORQUE TABLE 5A - COLD SERVICE PTFE COATED ASTM A320 GRADE L7 STUD BOLTS