What are Air Compressors? |

A compressor converts atmospheric air into compressed air for various industries. This guide explains its significance, operating principles, and types, as well as how to select the right model for your needs.

Compressors play a crucial role in modern industry. Since Austrian engineer Viktor Popp built the first compressor factory, compressed air has become a vital utility—often referred to as the fourth utility alongside electricity, water, and gas. Today, approximately 10% of the electricity used in manufacturing is used to generate compressed air.

Why they are important?

Compressed air is a mixture of gases, primarily nitrogen (78%) and oxygen (21%), that are pressurized to generate kinetic energy. By forcing air molecules into a smaller space, their density increases, causing them to move faster and generate energy. This process is performed by compressors, which draw in atmospheric air, compress it, and store it in a container for use.

Why do we compress air?

Air compressors convert regular atmospheric air into compressed air by forcing it into a smaller space. This compressed air is powerful and versatile and is used in many industries – from automotive manufacturing and transportation to construction and healthcare. Different industries require different types of compressors – whether it's a small, quiet unit for a dentist or a large compressor that powers an entire factory.

How do air compressors work?

Air compressors operate using two main technologies:

Dynamic compressors: These compressors increase air pressure by accelerating it with an impeller and then slowing it down in a diffuser. They are suitable for applications requiring very high air volumes.

Positive displacement compressors: These compressors capture atmospheric air in a cavity and reduce its size to increase pressure. They are more common than dynamic compressors and are available in several different designs.

Commonly used types of compressors

A reciprocating compressor, also known as a piston compressor, is a type of positive displacement compressor that uses a piston-crankshaft mechanism to compress air. The piston moves back and forth (reciprocal) within a cylinder, drawing in air on one stroke and compressing it on the next, ultimately transporting the air under high pressure to, for example, a storage tank.

Image.. fluidairedynamics.com

As the name suggests, screw compressors use rotational motion to compress air. Inside the compressor are a set of male and female rotors. These are designed differently so that air remains trapped between the rotors when they rotate simultaneously. The male rotor has convex lobes, while the female rotor has hollow cavities; this allows them to mesh without touching, thus achieving compression. Furthermore, the male rotor has slightly fewer lobes than the female, meaning it rotates faster and effectively drives the female rotor.

Image.. blog.exair.com

An inverter air compressor is a variable-speed compressor that uses an electronic inverter drive to adjust the motor speed to system demand, unlike fixed-speed compressors that cycle on and off. This adjustment allows the compressor to modulate its output and deliver only the required amount of cooling or air, resulting in higher energy efficiency, more precise temperature control, quieter operation, and a longer equipment lifespan.

Image.. rigidhvac.com

A scroll compressor, also called a spiral compressor or scroll pump, is a type of positive displacement compressor. It operates by internally compressing air or gas. Scroll compressors can be oil-lubricated or oil-free. The latter is most suitable for applications requiring clean, dry compressed air quality without oil contamination in the compression chamber.

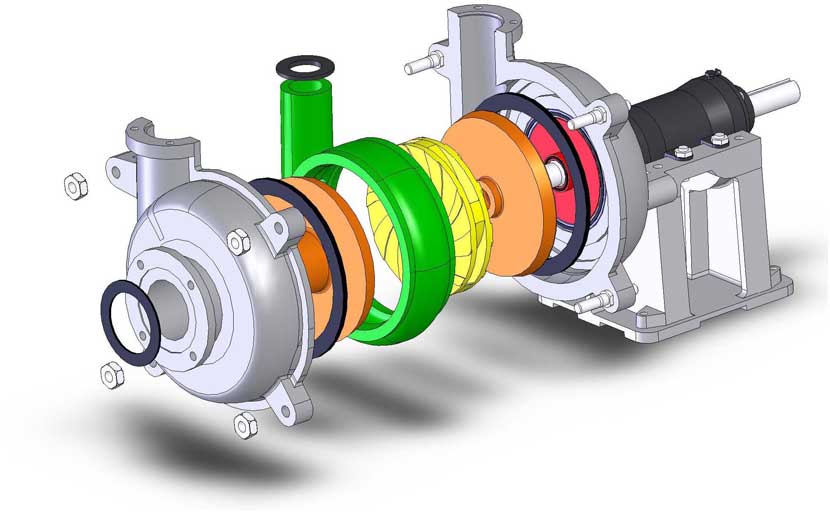

Image.. rasmech.com

Centrifugal air compressor belongs to speed air compressors and is a type of turbine compressor. It drives the air to rotate at high speed by the impeller, so that the gas obtains centrifugal force, thereby increasing the flow rate and pressure of the air after passing through the impeller.

Image.. fs-elliott.com

Choosing the Right Compressor

With so many options, choosing the right compressor can be overwhelming. It's important to consider the specific requirements of the application, whether you need clean air for sensitive environments or a powerful system for demanding tasks. Understanding the different types and technologies will help you choose the most efficient and cost-effective option for your needs.

Summary

Air compressors are essential to modern industry. Understanding the different types and technologies will help you choose the best compressor for your needs, ensuring both efficiency and cost-effectiveness.

Related Post(s)

A PUMP is a machine used for the purpose of transferring quantities of fluids and or gases from one place to another...