Gland packing: applications and advantages |

Gland packing is an essential component in many industrial applications. This flexible seal prevents leakage of liquids and gases in rotating equipment such as pumps and valves.

Gland packings are available in various materials, each with unique properties. Graphite gland packing offers excellent thermal conductivity and chemical resistance. PTFE gland packing excels in aggressive chemical environments. Glass fiber gland packing combines strength with cost-effectiveness.

For demanding applications, special variants such as 100% Gore gland packing, known for its superior performance, are available. PTFE plus gland packing offers improved stability, while Zebrax gland packing with aramid fibers delivers exceptional wear resistance. Graphite gland packing with reinforced nickel wires provides extra strength and electrical conductivity.

The correct selection and installation of gland packing is crucial for optimal performance and service life. This article discusses the different materials, applications, and advantages of gland packing, and provides practical tips for installation and maintenance to achieve the best results with the gaskets.

Whether you work in the chemical industry, food sector, or other industries, gland packing plays an important role in all processes. Below is a description of how to select the right gland packing for specific needs.

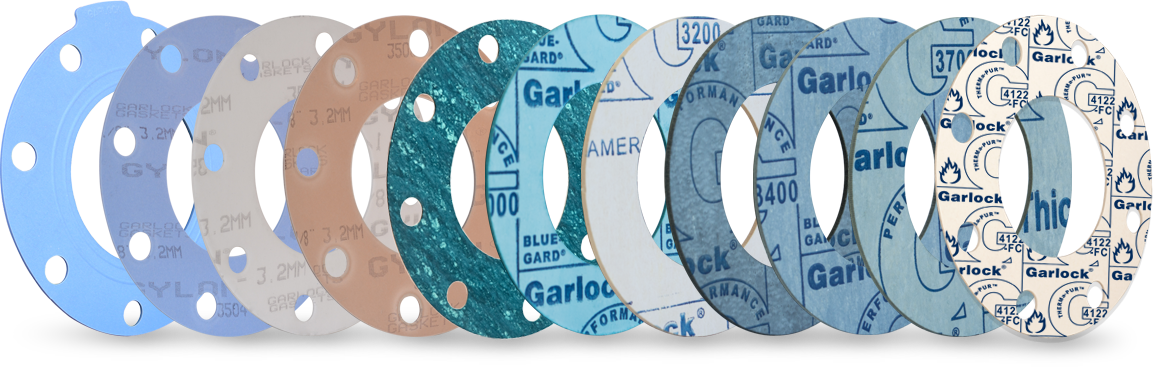

Gland packing materials and types

Choosing the right gland packing material is essential for optimal performance in a specific application.

There are several high-quality options, each with unique properties.

The most popular types and their characteristics are..

Graphite gland packing and PTFE gland packing compared

Graphite gland packing and PTFE gland packing are among our most popular products, each with its own strengths. Graphite gland packing excels in thermal conductivity and is ideal for high temperatures up to 450°C. It is resistant to most chemicals and gases, making it highly versatile.

PTFE gland packing, on the other hand, is the go-to choice for chemically aggressive environments. This inert material has a low coefficient of friction and is self-lubricating. For even better performance, PTFE plus gland packing is an option, combining extra strength and stability with the advantages of standard PTFE.

Graphite gland packing with reinforced nickel wires offers superior strength and electrical conductivity. This variant is ideal for applications where both properties are crucial. For extreme conditions, 100% Gore gland packing is recommended, known for its exceptional chemical resistance and low friction.

Each type has its specific area of application. Graphite gland packing is often the best choice for high temperatures, while PTFE gland packing excels in chemically demanding environments.

Glass fiber gland packing and aramid fibers

Glass fiber gland packing is a versatile solution that excels in various industrial applications. This material offers an excellent combination of strength, thermal stability, and chemical resistance. It is suitable for use in pumps, valves, and other rotating equipment at temperatures up to 290°C.

For even higher performance, Zeebrax gland packing with aramid fibers is an option. This advanced composition combines the advantages of glass fiber with the superior strength and wear resistance of aramid. Zeebrax gland packing with aramid fibers is ideal for demanding applications where conventional materials fall short, such as in the paper industry or with abrasive media.

Fiber glass gland packing is a cost-effective solution for many standard industrial processes. It offers good performance at moderate temperatures and pressures. Zeebrax gland packing with aramid fibers goes one step further and delivers exceptional performance in the most challenging environments.

Installation and maintenance of gland packing

Proper installation and maintenance of gland packing are crucial for optimal performance and service life. Whether you are working with graphite gland packing, PTFE gland packing, or other variants, a careful approach is essential. Here you will find practical guidelines for installation and tips for keeping your gland packing in top condition.

Assembly of gland packings

Step-by-step installation guide

- Cleaning: Start by thoroughly cleaning the packing chamber and shaft. Remove old packing residue and check for damage. For graphite gland packing with reinforced nickel wires, extra care is required to maintain the integrity of the wires.

- Cutting to size: Cut the new gland packing precisely to size with a sharp knife. With PTFE gland packing, it is crucial to maintain the correct cutting angle for an optimal gasket.

- Installation: Place the rings one by one in the packing chamber, rotating them around the shaft. For fiberglass Gland Packing, it is essential to press each ring firmly into place without using excessive force. Ensure that the ends of each ring are staggered 90 degrees from the previous one.

- Tightening: Tighten the packing gland evenly. For PTFE plus gland packing and zebrax gland packing with aramid fibers, it is important not to tighten too much to prevent material deformation.

- Running-in period: Run in the gland packing according to the manufacturer's recommendations. This ensures optimum performance and service life.

Tips for long-lasting performance

- Regular inspection: Check regularly for leaks and wear, especially in high-load applications with 100% Gore gland packing or graphite gland packing. Keep a logbook for trend analysis.

- Correct adjustment: Gradually adjust the packing pressure if there are signs of leakage. Avoid excessive tightening, which can lead to shaft damage and increased friction. For PTFE gland packing, a lighter adjustment is often sufficient.

- Lubrication: Keep the shaft or spindle clean and well lubricated. For fiberglass gland packing and zebrax gland packing with aramid fibers, use a compatible lubricant to reduce friction and extend service life.

- Monitoring: Keep an eye on operating conditions such as temperature and pressure. Sudden changes can affect the performance of gland packing, especially in the case of graphite gland packing with reinforced nickel wires. If necessary, adjust the choice of packing to suit changing conditions.

- Timely replacement: Replace the gland packing according to the recommended intervals or when there are clear signs of wear. This prevents unplanned downtime and costly repairs.

Gland packing plays a crucial role in various industrial sectors. From the chemical industry to the food sector, this versatile sealing solution ensures reliable performance in a wide range of environments.

| www.wagnergaskets.nl/stopbuspakking/ |

Related Post(s)

Flange gaskets are used to create a static seal between two flanges faces, at various operating conditions, with varied pressure and temperature ratings...