|

Spiral wound gaskets for flanged connections |

The many advantages of spiral wound SPW) gaskets are found in conventional and nuclear power plants, chemical and petrochemical plants, refineries, equipment construction, boiler construction, high-pressure pipes with flange connections and in aerospace. Different variants of this gasket for a wide range of applications are available.

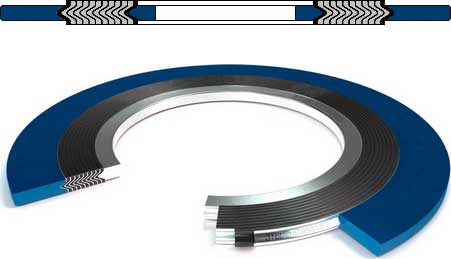

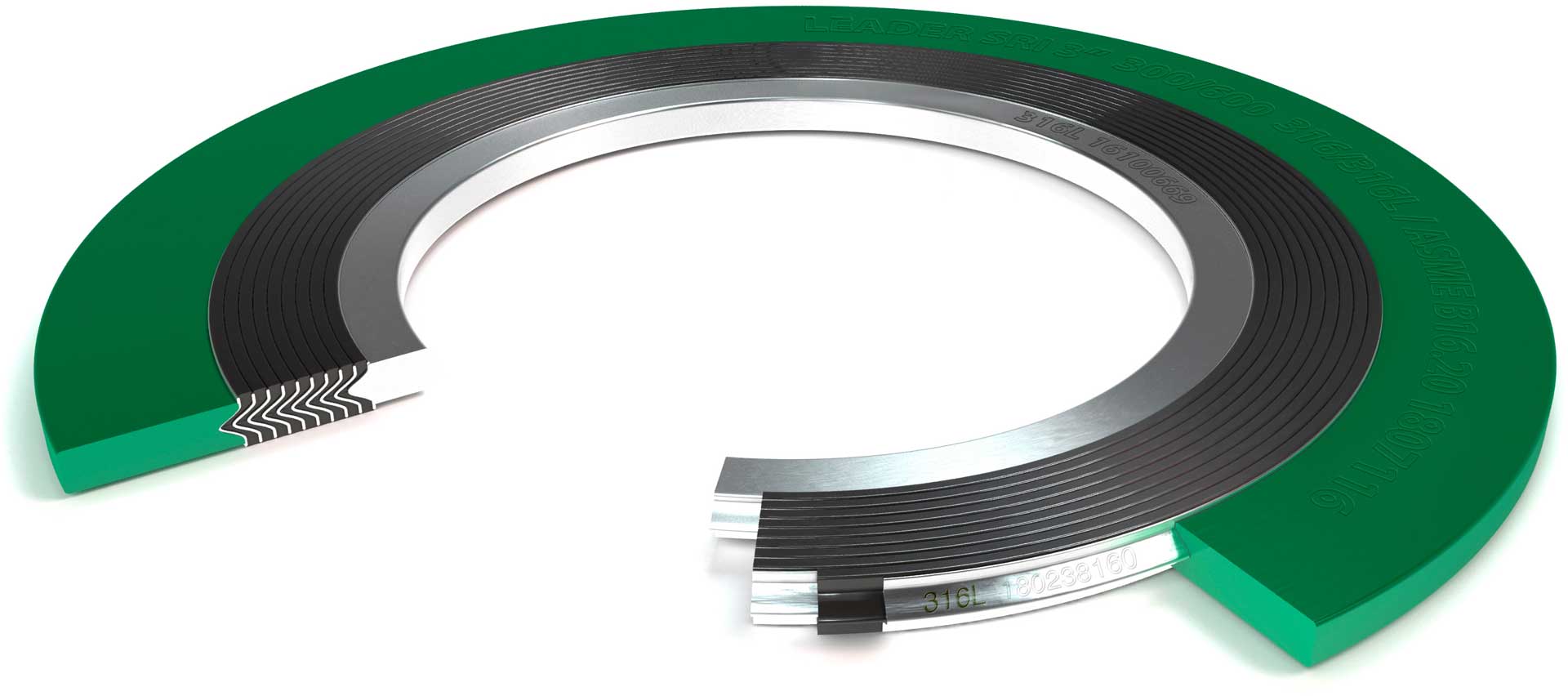

Spiral wound gaskets are characterised by a high degree of precision. This makes it possible to integrate a filler material while winding a profiled metal strip.

The high quality of spiral wound gaskets is also achieved by the high quality of the expanded Graphite or PTFE. In this case, the V-profile metal strip is manufactured from different metal materials, with the V-shaped cross-section that brings about the improvement in the resilience of the gasket.

Spiral wound gaskets come with and without inner and outer ring. The texture is designed to allow universal application, and substances such as water, , steam, acids and gases can be easily sealed. Resistant variants of spiral wound gaskets can also be produced for particularly chemical products.

The secret

The key of the spiral wound gasket is a wound steel strip in a V-shape. Under pressure, it presses against the flanges and simultaneously compresses the filler material.

Profiles

spiral wound gasket without inner and outer ring for force, groove and spring applications.

spiral wound gasket with inner ring, for male and female flanges.

spiral wound gasket with centring ring, for flanges with and without sealing strip.

spiral wound gasket with centring ring and inner ring, for flange joints with and without sealing strip.

![]() the

inventor of the spiral wound gasket

the

inventor of the spiral wound gasket

Flexitallic was born from the revolutionary invention of the spiral gasket in

Trenton, New Jersey. It was developed for use in marine steam engines that were notorious for their

low efficiency and poor power transmission to speed. Suddenly, the use of the Spiral Wound Gasket

unlocked the energy of these engines and increased the efficiency and speed of marine vessels.

Since its foundation in 1912, Flexitallic continues to be the sealing company that industry innovators

look to when choosing products and materials to develop and implement new technologies.

Related Post(s)

Dimensions Spiral Wound Gaskets ASME B16.20 used with RF flanges ASME B16.5...