|

|

Spiral-wound vs Kammprofile gaskets (grooved) |

Both spiral wound and kammprofile gaskets or grooved gaskets are used in various applications, such as refineries, petrochemical plants, power plants, etc. In recent years, the use of comb profile gaskets seemed to gain traction over conventional spiral wound gaskets, as they typically offer better sealing and longer life.

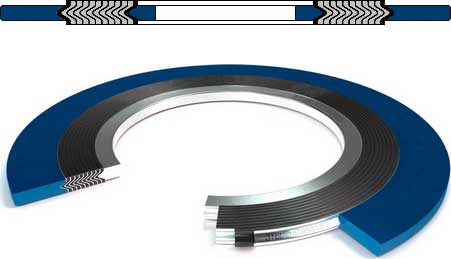

Spiral wound gaskets

They basically consist of alternating layers of compressible filler material and a metal strip (winding) wound in a manner similar to the grooves of a gramophone record. The most common method of centring this type of gasket is by using a metal outer ring. Besides centring the gasket, this metal outer ring also limits the compression of the gasket. Once the gasket is installed, the filler material is pushed between the layers, creating a seal between the flange faces and covering any imperfections.

Initially, asbestos was a commonly used filler material in gaskets. However, due to health reasons, the use of asbestos is no longer allowed and today asbestos is replaced by other materials such as rubber, PTFE, graphite, etc.

Dimensions and sizes of spiral gaskets for ASME B16.5 (flanges with a nominal size up to NPS 24) and ASME B16.47 (flanges with a nominal size equal to or greater than NPS 26) are defined in the ASME B16.20 standard (‘Metallic Gaskets for Pipe Flanges’).

Spiral wound gaskets have a number of drawbacks

- They are very susceptible to damage and ‘springy’ if dropped, bumped or not handled properly.

- It may often be necessary to provide them with inner rings as well. If inner rings are not provided, the windings run the risk of buckling, significantly reducing the load that can be safely applied and maintained on them. Adding an inner ring gives an additional compression-limiting stopper and provides a heat and corrosion barrier that protects the gasket windings and prevents flange erosion. It is common for the material of the inner ring to be the same as that of the metal winding.

- Large-sized gaskets are generally very difficult to handle, as their windings tend to come outwards.

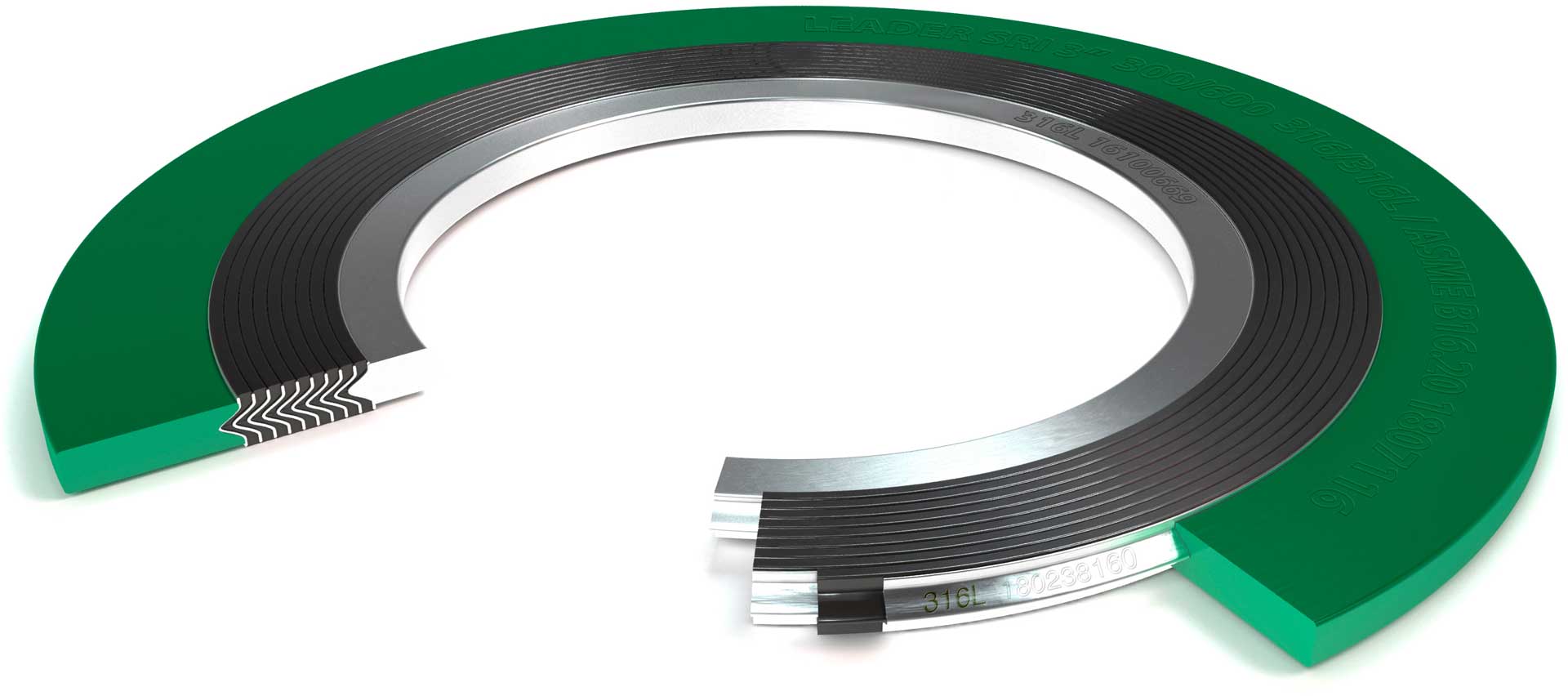

Camprofile gaskets

Camprofile gaskets consist of a solid metal core with concentric serrations and are faced on both sides with a non-metallic material such as graphite, various types of PTFE, etc.

Once the gasket is installed, the soft non-metallic material is pressed into the serrated grooves of the metal core. As a result, with increasing compressive stress, multiple concentric high-pressure seals form along the surface of the gasket.

Unlike a spiral gasket, all compressive force is exerted on the graphite layer of the camprofile, resulting in a very tight seal. Because the camprofile is basically solid metal, unlike the alternating layers of metal and filler used in spiral wound gaskets, it is extremely resilient and easy to handle, even with large diameters.

Camprofile gaskets compress significantly less than spiral-wound gaskets, allowing them to be loaded faster and with less risk of non-parallel flanges.

Price-wise, camprofile gaskets are significantly more expensive. However, the higher start-up costs are offset by avoiding costly, unplanned downtime and production losses.

Spiral wound gaskets may have a slight advantage if the flanges are too close together and if the gasket is expected to be susceptible to mechanical damage or abuse during installation, as the graphite layer is more vulnerable to mechanical damage. In some cases, spiral wound gaskets are also more resistant to oxidation because the windings hold the graphite in place and protect it. On the other hand, camprofile gaskets are more tolerant to defects in the sealing surface and seal more effectively in volatile emissions.

In summary, although there seems to be a shift towards the use of camprofile gaskets in recent years, but when properly made and installed, both gasket types offer reliable seals.

Related Post(s)

Dimensions Spiral Wound Gaskets ASME B16.20 used with RF flanges ASME B16.5...

Dimensions of Grooved (Camprofile) Gaskets ASME B16.20 used with Raised Face flanges ASME B16.5...