Radiographic Testing (RT) |

History of radiographic testing

The history of radiographic testing actually involves two beginnings. The first commenced with

the discovery of x-Rays by Wilhelm Conrad Röntgen in 1895 and the second with the announcement

by Marie Curie, in December of 1898, that the demonstrated the existence of a new radioactive material

called "Radium".

More about Curie and Röntgen can be found on the World Wide Web.

Marie Curie

W.C. Röntgen

What is Radiographic Testing?

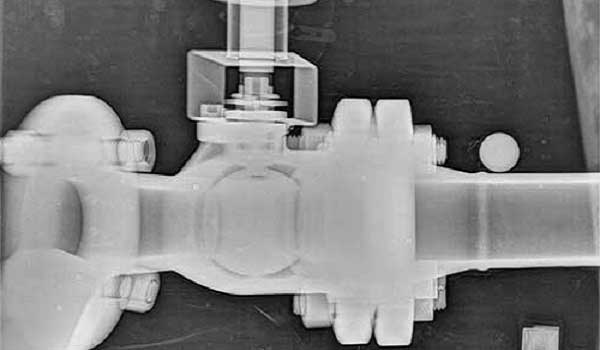

Radiographic Testing (RT or X-ray or Gamma ray) is a non-destructive testing (NDT) method that examines the volume of a specimen. Radiography (X-ray) uses X-rays and gamma-rays to produce a radiograph of a specimen, showing any changes in thickness, defects (internal and external), and assembly details to ensure optimum quality in your operation.

RT usually is suitable for testing welded joints that can be accessed from both sides, with the exception of double-wall signal image techniques used on some pipe. Although this is a slow and expensive NDT method, it is a dependable way to detect porosity, inclusions, cracks, and voids in weld interiors.

RT makes use of X-rays or gamma rays. X-rays are produced by an X-ray tube, and gamma rays are produced by a radioactive isotope.

Water cooled X-ray tube

- K - cathode (electron Reference(s))

- A - anode (target electrons)

- C - cooling Water

- Uh - heating voltage

- Ua - accelerating voltage

- X - X-radiation (X-rays)

The method is based on the same principle as medical radiography in a hospital. A piece of radiographic film is placed on the remote side of the material under inspection and radiation is then transmitted through from one side of the material to the remote side where the radiographic film is placed.

The radiographic film detects the radiation and measures the various quantities of radiation received over the entire surface of the film. This film is then processed under dark room conditions and the various degrees of radiation received by the film are imaged by the display of different degrees of black and white, this is termed the film density and is viewed on a special light emitting device.

Discontinuities in the material affect the amount of radiation being received by the film through that particular plane of the material. Qualified inspectors can interpret the resultant images and record the location and type of defect present in the material. Radiography can be used on most materials and product forms, e.g. welds, castings, composites etc.

Radiographic testing provides a permanent record in the form of a radiograph and provides a highly sensitive image of the internal structure of the material.

The amount of energy absorbed by the object depends on its thickness and density. Energy not absorbed by the object causes exposure of the radiographic film. These areas will be dark when the film is developed. Areas of the film exposed to less energy remain lighter. Therefore, areas of the object where the thickness has been changed by discontinuities, such as porosity or cracks, will appear as dark outlines on the film. Inclusions of low density, such as slag, will appear as dark areas on the film, while inclusions of high density, such as tungsten, will appear as light areas.

All discontinuities are detected by viewing the weld shape and variations in the density of the processed film. This permanent film record of weld quality is relatively easy to interpret if personnel are properly trained. Only qualified personnel should conduct radiography and radiographic interpretation because false readings can be expensive and can interfere seriously with productivity, and because invisible X-ray and gamma radiation can be hazardous.

Standards

ASTM International (ASTM)

- ASTM E 94, Standard Guide for Radiographic Examination

- ASTM E 155, Standard Reference Radiographs for Inspection of Aluminum and Magnesium Castings

- ASTM E 592, Standard Guide to Obtainable ASTM Equivalent Penetrameter Sensitivity for Radiography of Steel Plates1/4 to 2 in. [6 to 51 mm] Thick with X Rays and 1 to 6 in. [25 to 152 mm] Thick with Cobalt-60

- ASTM E 747, Standard Practice for Design, Manufacture and Material Grouping Classification of Wire Image Quality Indicators (IQI) Used for Radiology

- ASTM E 801, Standard Practice for Controlling Quality of Radiological Examination of Electronic Devices

- ASTM E 1030, Standard Test Method for Radiographic Examination of Metallic Castings

- ASTM E 1032, Standard Test Method for Radiographic Examination of Weldments

- ASTM 1161, Standard Practice for Radiologic Examination of Semiconductors and Electronic Components

- ASTM E 1648, Standard Reference Radiographs for Examination of Aluminum Fusion Welds

- ASTM E 1735, Standard Test Method for Determining Relative Image Quality of Industrial Radiographic Film Exposed to X-Radiation from 4 to 25 MeV

- ASTM E 1815, Standard Test Method for Classification of Film Systems for Industrial Radiography

- ASTM E 1817, Standard Practice for Controlling Quality of Radiological Examination by Using Representative Quality Indicators (RQIs)

- ASTM E 2104, Standard Practice for Radiographic Examination of Advanced Aero and Turbine Materials and Components

American Society of Mechanical Engineers (ASME)

- BPVC Section V, Nondestructive Examination.. Article 2 Radiographic Examination

American Petroleum Institute (API)

- API 1104, Welding of Pipelines and Related Facilities.. 11.1 Radiographic Test Methods

International Organization for Standardization (ISO)

- ISO 4993, Steel and iron castings - Radiographic inspection

- ISO 5579, Non-destructive testing - Radiographic examination of metallic materials by X- and gamma-rays - Basic rules

- ISO 10675-1, Non-destructive testing of welds - Acceptance levels for radiographic testing - Part 1.. Steel, nickel, titanium and their alloys

- ISO 11699-1, Non-destructive testing - Industrial radiographic films - Part 1.. Classification of film systems for industrial radiography

- ISO 11699-2, Non-destructive testing - Industrial radiographic films - Part 2.. Control of film processing by means of reference values

- ISO 14096-1, Non-destructive testing - Qualification of radiographic film digitisation systems - Part 1.. Definitions, quantitative measurements of image quality parameters, standard reference film and qualitative control

- ISO 14096-2, Non-destructive testing - Qualification of radiographic film digitisation systems - Part 2.. Minimum requirements

- ISO 17636, Non-destructive testing of welds - Radiographic testing of fusion-welded joints

- ISO 19232, Non-destructive testing - Image quality of radiographs

European Committee for Standardization (CEN)

- EN 444, Non-destructive testing; general principles for the radiographic examination of metallic materials using X-rays and gamma-rays

- EN 462-2, Non-destructive testing - image quality of radiographs - Part 2.. image quality indicators (step/hole type) - determination of image quality value

- EN 462-3, Non-destructive testing - Image quality of radiogrammes - Part 3.. Image quality classes for ferrous metals

- EN 462-4, Non-destructive testing - Image quality of radiographs - Part 4.. Experimental evaluation of image quality values and image quality tables

- EN 462-5, Non-destructive testing - Image quality of radiographs - Part 5.. Image quality of indicators (duplex wire type), determination of image unsharpness value

- EN 584-1, Non-destructive testing - Industrial radiographic film - Part 1.. Classification of film systems for industrial radiography

- EN 584-2, Non-destructive testing - Industrial radiographic film - Part 2.. Control of film processing by means of reference values

- EN 1330-3, Non-destructive testing - Terminology - Part 3.. Terms used in industrial radiographic testing

- EN 1435, Non-destructive testing of welds - Radiographic testing of welded joints

- EN 2002-21, Aerospace series - Metallic materials; test methods - Part 21.. Radiographic testing of castings

- EN 10246-10, Non-destructive testing of steel tubes - Part 10.. Radiographic testing of the weld seam of automatic fusion arc welded steel tubes for the detection of imperfections

- EN 12517-1, Non-destructive testing of welds - Part 1.. Evaluation of welded joints in steel, nickel, titanium and their alloys by radiography - Acceptance levels

- EN 12517-2, Non-destructive testing of welds - Part 2.. Evaluation of welded joints in aluminium and its alloys by radiography - Acceptance levels

- EN 12679, Non-destructive testing - Determination of the size of industrial radiographic source - Radiographic method

- EN 12681, Founding - Radiographic examination

- EN 13068, Non-destructive testing - Radioscopic testing

- EN 14096, Non-destructive testing - Qualification of radiographic film digitisation systems

- EN 14784-1, Non-destructive testing - Industrial computed radiography with storage phosphor imaging plates - Part 1.. Classification of systems

- EN 14584-2, Non-destructive testing - Industrial computed radiography with storage phosphor imaging plates - Part 2.. General principles for testing of metallic materials using X-rays and gamma rays

Related Post(s)

OSI can be applied for the production of overview images (the so-called shadow images) for the detection of installations or add-ons in...

The purpose of the vacuum box technique of bubble leak testing is to detect leaks in a pressure boundary that cannot be directly pressurized...