Heat Affected Zone (HAZ) |

The heat affected zone (HAZ) is an unmelted area of metal whose material properties have changed due to exposure to high temperatures.

The changes in material properties are usually the result of welding or cutting

under high heat, and the area between the weld or cut and the (unaffected) base metal is called

the HAZ.

The severity and extent of the hazardous zone area can vary depending on the properties of the materials,

the concentration and intensity of the heat, and the welding or cutting process used.

What causes heat-affected zones?

The heating associated with welding and/or cutting typically occurs at temperatures that reach and often exceed the melting point of the material, depending on the process used. However, the thermal cycle of heating and cooling associated with these processes differs from the processing previously performed on the parent material. This leads to a change in the microstructure related to the heating and cooling process.

The size of a heat-affected zone (HAZ) is influenced by the rate of thermal diffusivity, which depends on a material's thermal conductivity, density, and specific heat, as well as the amount of heat entering the material. Materials with high thermal diffusivity can transfer heat variations more quickly, meaning they cool faster and therefore reduce the width of the HAZ.

Materials with a lower coefficient, on the other hand, retain heat, resulting in a wider HAZ. In general, the size of the HAZ depends on the amount of heat applied, the duration of the exposure, and the properties of the material itself. When a material is exposed to larger amounts of energy over a longer period, the HAZ becomes larger.

Regarding welding procedures, low-heat-input processes cool faster, resulting in a smaller flammable zone (HAZ), while high-heat-input processes have a slower cooling rate, resulting in a larger flammable zone (HAZ) in the same material. Furthermore, the size of the HAZ increases as the welding process speed decreases. Weld geometry is another factor that affects the size of the HAZ, as it affects the heat sink. A larger heat sink generally results in faster cooling.

High temperature cutting operations can also cause a HAZ and, similarly to welding procedures, those processes that operate at higher temperatures and slow speeds tend to create a larger HAZ, while lower temperature or higher speed cutting processes tend to reduce the HAZ size. The width of the HAZ from the cut edge is determined by the cutting process, cutting speed, and the material properties and thickness.

Different cutting processes have different effects on the flammable zone (HAZ), regardless of the material being cut. For example, shearing and waterjet cutting do not create a HAZ because they do not heat the material. Laser cutting, on the other hand, creates a small HAZ because the heat is only applied to a small area. Plasma cutting, on the other hand, results in a medium HAZ, with higher currents allowing for a higher cutting speed and therefore a narrower HAZ.

Oxyfuel cutting, on the other hand, creates the widest HAZ due to the high heat, low speed, and flame width. Arc welding falls between these two extremes, with the heat input of individual processes varying.

HAZ zones

While the HAZ zone occurs between the welding or cutting area and the unaffected base metal, the hazardous zone itself has several zones, depending on how close they are to the point where the cutting or welding heat is applied to the material.

The cutting or welding zone is the fluid region where the process itself takes place and borders the melting boundary. The melting boundary is the boundary of the melting zone where the liquid and solid phases of the metal coexist. Further from the welding or cutting zone lies the HAZ itself, where the unmelted base metal has undergone microstructural changes.

In conventional steels, the HAZ can be divided into the grain groove zone (closest to the heated area), the grain refined zone, the partially transformed (intercritically heated) zone, and the tempered zone. In other materials, which do not undergo solid-state phase transformation during cooling, it is common to see a grain growth zone and a recrystallized zone, with some evidence of a tempered zone. Outside of these HAZ regions lies the unaffected base metal.

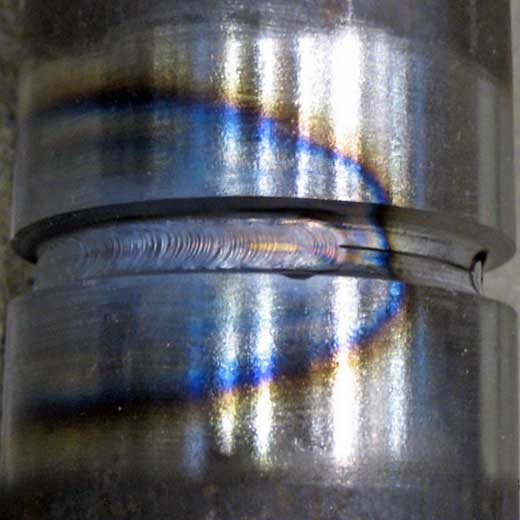

The various HAZ regions are formed by temperature differences in the base metal, further from the weld or cut itself. This should not be confused with the series of visible colored bands caused by surface oxidation near a weld in stainless steel.

The temper colors represent much lower temperatures than those that form the heat-affected zone (HAZ) and extend some distance beyond the actual HAZ. These different colors, also called heat tint, indicate the temperature the metal reaches.

What does the Color tell?

Various temperatures during the production process create different tints in the HAZ. These tints range from light yellow to dark blue, depending on the temperature.

| Color | Cutting temperature |

| Light yellow | 290º C |

| Straw yellow | 340º C |

| Yellow | 370º C |

| Brown | 390º C |

| Purple brown | 420º C |

| Dark purple | 450º C |

| Blue | 540º C |

| Dark blue | 600º C |

Heat tint colors depend on the materials oxidation resistance. Metals with a higher chromium content exhibit less intense coloration because they are more resistant to oxidation.

The use of shielding gas and electrode coatings can also reduce heat tint, as they partially protect the metal from oxidation. Rougher surfaces, on the other hand, oxidize more quickly, resulting in darker colors. Furthermore, paint, oil, rust, and even fingerprints can affect heat tint, although they do not affect the extent of the hazard zone itself.

How to Reduce the Heat Affected Zone

Reducing the presence or effect of the heat affected zone can help alleviate the associated problems of HAZ cracking, corrosion, embrittlement etc.

This can be achieved through heat treatment after welding or cutting. The heat treatment applied depends on the required properties and the desired changes – it can be a precipitation hardening treatment or a softening treatment, depending on the material. However, this process can be expensive and time-consuming and may not offer a complete solution. Heat treatment is also limited by the relative size of the part and the torch or furnace used.

Machining is the most effective way to remove the entire heat-affected zone (HAZ), but this can reduce material yield and increase labor and machine time.

Heat tint from oxidation can also be removed by grinding or sanding with moderately coarse sandpaper. This exposes the underlying layer and activates the self-passivation of the chrome, although it can also weaken the part.

However, many problems can be prevented by choosing the appropriate welding or cutting process for the material to minimize the HAZ.

Summary

The heat-affected zone (HAZ) is an unavoidable component of high-temperature

metal cutting and welding. Its cause is overheating of the metal during these processes, which can

affect material properties.

This can be largely controlled and mitigated by engaging a reliable metalworking expert and/or supplier

with the necessary expertise to minimize the (HAZ.

Related Post(s)

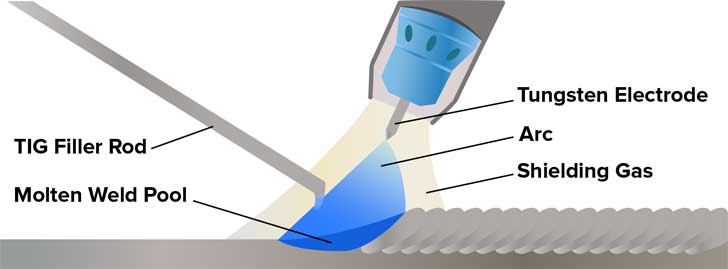

Gas tungsten arc welding (GTAW), also known as Tungsten Inert Gas (TIG) welding became an overnight success in the 1940s for joining magnesium and aluminium...