Orbital Welding |

When high quality results are required, orbital welding is the first choice for connecting pipes.

The welding torch - in most cases, TIG welding (Tungsten Inert Gas) is used - travels around the pipes to be connected, guided by a mechanical system.

The name orbital welding comes of the circular motion of welding tool around the workpiece. In general, orbital welding technology includes coverage two main application areas..

- Tube to tube / pipe to pipe joining

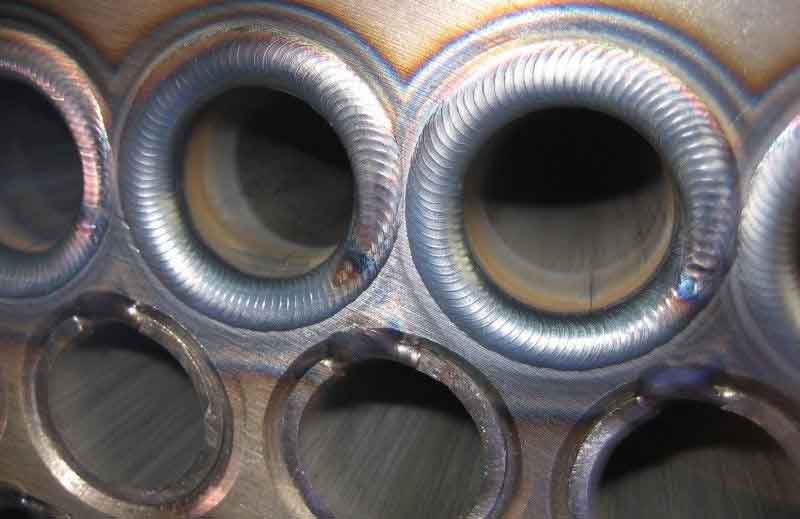

- Tube-to-tubesheet welding

In the first group, all kinds of pipe connections are included.. butt welding and welding flanges, bends, T-fittings and valves, i.e. the complete requirements for pipes and tubes.

The second group concerns production of boilers and heat exchangers and includes the various welding tasks related to tube-to-tubesheet welding operations.

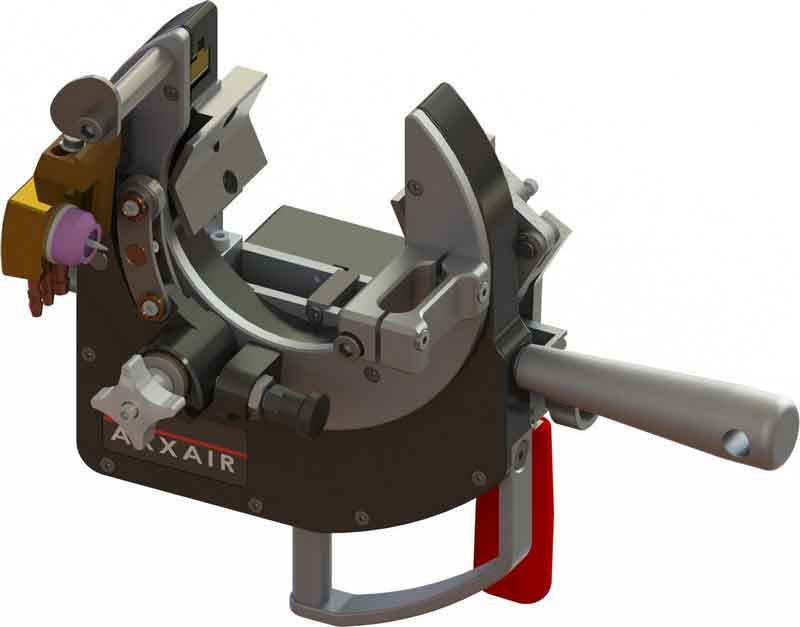

Mechanical System Orbital for Welding

Reasons to select Orbital Welding

The decision for the use of mechanised or automatic orbital TIG welding can be taken for different reasons.. economic, technical, organisational, and others may be more or less important or even become the decisive factor. The orbital welding process offers a large range of benefits which qualifies it for industrial applications. The major advantages are..

Increased productivity compared to manual welding

- Compared to manual TIG welding, the mechanised or automatic process leads to enhanced productivity. Repetitive work in the workshop or on-site complicated assembly jobs - orbital welding equipment guarantees that approved weld sequences are reliably repeated, hence time-consuming repair work will be reduced to a minimum.

Consistent excellent weld quality

- Generally, the weld quality obtained by mechanised equipment is superior to thatof manual welding. Once an adequate weld program has been developed, the weld cycle can be repeated as often as necessary, without deviations and virtually without weld defects.

Required skill levels of the operators

- Certified welders are difficult to find and well remunerated. However, after appropriate training, skilled mechanics are able to operate orbital welding equipment perfectly and obtain excellent results. By using this equipment expenditure on personnel can be reduced.

Environment

- Orbital welding can be executed even under harsh environmental conditions. Restricted space or access, lack of visibility, presence of radiation; once the weld head is positioned properly, the weld can be carried out without difficulty from a safe distance; often supported by a video transmission.

Traceability - Quality Control

- Modern orbital welding equipment is designed for real-time monitoring of the aaffecting weld parameters; a complete weld protocol can be generated and stored or printed out. Sophisticated data acquisition systems operate in the background, if they are connected directly to a superior quality management system; automatic data transfer takes place without any interruptions to the weld procedure.

Orbital Tube-to-Tubesheet Welding

Industries which apply the orbital TIG Welding Process

- Aeronautics/Aerospace Industry

- Food and beverage industries

- Pharmaceutical and Biotechnology industries

- Manufacture of Semi-Conductor devices

- Chemical industries

- Fossil and Nuclear Power plants

Gases

Welding Gases

Argon is commonly used as shielding gas in the TIG process. It provides good arc striking characteristics and excellent arc stability even at low amperages, the energy of the arc is confined to a narrow area. Argon is also compatible with all types of base materials.

Shielding gas for standard TIG welding purposes should have a purity of 4.5, i.e. a purity level of 99.995%. Metals which are classified as delicate to weld for example; titanium, tantalum, zirconium and their alloys require a purity of at least 4.8, which means a purity level of 99.998%.

To increase the weld energy, 2% to 5% hydrogen can be added to the argon. As well as a higher energy input of 10% to 20% resulting in a better penetration and faster welding speeds, argon / hydrogen mixtures have reducing properties helping to protect the molten metal against the influence of oxygen from the surrounding atmosphere. However, mild and carbon steels absorb hydrogen with the possible result of porosity and cold cracking, so the use of hydrogen containing gas mixtures is not recommended; for the welding of aluminium and titanium they are strictly forbidden.

The weld energy can also be increased by argon/helium mixtures with helium contents of 20%, 50% or 70% or even pure helium. Helium has no detrimental effects on titanium, so it is used especially to weld the pure metal or titanium containing alloys. Mixtures of argon, helium and nitrogen are used to weld Duplex and Super Duplex steels.

Unlike argon, helium is a good heat conductor. The arc voltage under helium is much higher than under argon, so the energy content of the arc is strongly increased. The arc column is wider and allows deeper penetration. Helium is applied for the welding of metals with high heat conductivity like copper, aluminium and light metal alloys. As helium is a lightweight gas, compared to argon its flow rate for identical gas coverage must be increased two to three times.

The following table indicates the qualification of different welding gases and mixtures according to the base materials to be joined.

| Ar | Ar+H2 | Ar+He | Ar+N2 | He | |

| Mild steel Carbon steel |

+++ | ++ | ++ | + | ++ |

| Austenitic steel | +++ | ++ | ++ | + | ++ |

| Duplex steel Super duplex steel |

++ | ++ | ++ | +++ | ++ |

| Copper | +++ | X | +++ | ++ | +++ |

| Aluminium | +++ | X | +++ | + | +++ |

| Titanium | +++ | X | +++ | X | +++ |

Ar Argon | N2 Nitrogen | H2 Hydrogen | He Helium | +++ Recommended | ++ Possible | + Not to be used | X Prohibited

Backing Gas

During orbital welding, the inner surface of the tubes must be protected against oxidation. Therefore, the interior of the tube system is purged by backing gas. The purity of the backing gas depends on the required weld quality. Before the weld can be started, a sufficient purge time must elapse, allowing the backing gas to remove the oxygen out of the system.

The remaining oxygen content of the backing gas can be analysed at the outlet; if it has decreased to an acceptable value, the welding operation can begin. Usually in the case of UHP applications (Ultra High Purity) the oxygen level must fall below 10 PPM (Parts per Million), i.e. less than 0.001%.

Expert information.. The supply of ultrapure process gas requires that it passes through the tubes without being contaminated by moisture, oxygen, particles or other contaminants.

During welding, the specified values of flow rate and internal pressure of the backing gas must be respected and kept constant. The internal pressure must be controlled because excessive pressure will produce a root weld with a concave surface at the outside or, even worse, cause a weld bead short circuit.

If tubes with small diameters below 9.52mm (3/8in) are welded, the internal pressure can be used to prevent any excess of convexity or inside diameter reduction.

Expert information.. A light heat tint, due to remaining oxygen in the backing gas, can be removed by passivation.

Orbital Welded Pipes and Fittings

Reference(s) for this page www.polysoude.com

Related Post(s)

The use of lasers is a relatively new way of welding. Although the concept is still the same - using heat to join two materials - the way heat is delivered by lasers is quite unique...