Welding stainless steel to other steels |

Welding austenitic stainless steel to carbon steel and low-alloy steel is a commonly used method in the process and construction industry.

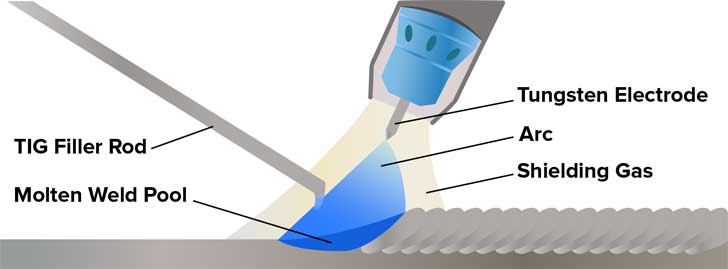

Welding dissimilar metal with stainless steel can be performed with most full welding methods, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas).

Welding procedures with filler materials (consumables) allow better control of the corrosion resistance and mechanical properties of the joint. When choosing the consumable material, the weld is considered stainless rather than carbon steel. Overalloyed consumables are used to prevent dilution of alloying elements in the melt zone of the stainless steel.

Combinations of dissimilar metal

The most common combinations of dissimilar steel with stainless steel are common carbon or low-alloy structural grades and austenitic stainless steels such as 1.4301 ,(304), or 1.4401 (316).

Welding conditions

Carbon and alloy steels with less than 0.20% carbon normally do not require preheating when welding to austenitic stainless steels. Carbon and alloy steels with carbon content greater than 0.20% may require preheating. Joints with high tensile strength and material thicknesses greater than 30 mm generally do require preheating, with temperatures of 150 °C usually sufficient.

Carbon steels can be more susceptible to hydrogen-related defects than austenitic stainless steels and it is therefore advisable to dry welding consumables carefully.

When welding stainless steel to galvanised steel, the zinc layer around the area to be joined should be removed before welding. Molten zinc present in the melting zone of the weld can lead to embrittlement or reduced corrosion resistance of the finished weld.

Selection of welding consumables (filler materials)

Ambient temperatures

Although a standard 308 type filler material can be used for joining type 304 stainless steel to carbons steel, but high-alloy filler materials such as types 309 are preferable.This should help prevent cracking in the weld dilution zone, which can be a problem if a type 308 filler is used, where the ferrite content may be too low and martensite may form on cooling.

High operating temperatures

If the welded parts are used at higher temperatures (above 425°C), the differences in thermal expansion rates of the steels and the filler material can lead to thermal fatigue cracking. Long exposure times at these temperatures of welds with elevated ferrite levels can lead to embrittlement due to the formation of sigma phases.

Nickel-based fillers (e.g. Inconel) produce welds with lower thermal expansion rates than stainless steel fillers and may therefore be preferred.

Risk of bimetallic corrosion when welding between carbon steel and stainless steel

Unprotected welds exposed to aggressive environments, such as immersion in seawater, can lead to sacrificial corrosion of the less noble carbon steel part.

However, repair of the surface coating after welding would normally be necessary to ‘restore’ the corrosion protection of the carbon steel.

If this re-coating/painting is allowed to overlap on the weld, then the weld is not at risk of bimetallic corrosion in any environment as long as the coating is good. Ideally, the weld is covered so that only the ‘master‘ stainless steel is ultimately exposed. This ensures that no galvanic corrosion cells can form across the weld, where there is a ‘gradient’ in composition.

Reference(s).. various welding associations

Related Post(s)

Gas tungsten arc welding (GTAW), also known as Tungsten Inert Gas (TIG) welding became an overnight success in the 1940s...