|

Choke valves |

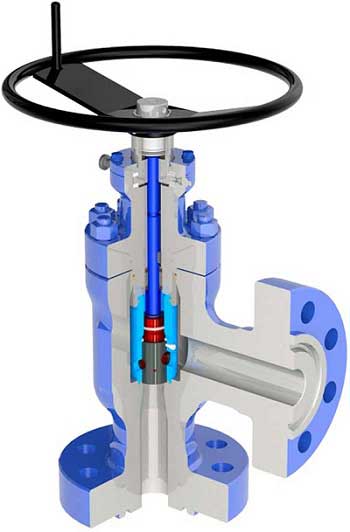

A choke valve is a type of flow control valve used to control the flow of fluids, such as gases or liquids, in a pipeline. Choke valves are typically used in the oil and gas industry to control the flow of well fluids, such as oil or natural gas, from a wellhead to a production facility.

The valve is designed to reduce the flow rate by creating a restriction in the pipeline, which can be adjusted to achieve the desired flow rate. This is usually accomplished by using a tapered orifice or variable orifice, which can be adjusted to increase or decrease the restriction in the pipeline.

Choke Valve Image From www.iamquam.it

Choke Valve Image From www.iamquam.it

How does a choke valve work?

A choke valve works by controlling the flow of fluid through a restriction in the valve, which can be adjusted to achieve the desired flow rate. The restriction is usually created by a small opening through which the fluid must pass. With a fixed choke valve, the opening has a fixed size and cannot be adjusted, whereas with an adjustable choke valve, the opening can be adjusted to vary the restriction in the pipeline.

Choke valves are often used in the oil and gas industry to control the flow rate of well fluids, such as oil or natural gas, from a wellbore to a production facility. In addition, choke valves are also used in many other process industries, such as power generation, chemicals and water treatment.

Different types of choke valves

- Conventional Choke Valves

These are the most common types of choke valves and have a fixed or adjustable orifice that creates a restriction in the pipeline. They are typically used in low-pressure, low-flow applications. - Positive Choke Valves

These valves use a piston or plug to create a restriction in the pipeline. They are typically used in high-pressure, high-flow applications. - Multi-Stage Choke Valves

These valves have multiple orifices or restriction stages that can be adjusted independently. They are typically used in applications where precise flow control is required. - Automatic Choke Valves

These valves have built-in actuators and control systems that automatically adjust the flow rate based on input from sensors or control systems. They are typically used in applications where the flow rate must be continuously adjusted. - Hydraulic choke valves

These valves use a fluid-driven actuator to control flow. They are often used in remote or hazardous locations where manual adjustments are not possible.

In addition to the above types of choke valves, other variations include "self-operating choke valves" that can be operated by pressure changes of the fluid itself, and "smart choke valves" that use advanced technology to control flow.

Certification process or governing body for choke valves

- American Petroleum Institute (API)

The API is a trade organization for the oil and gas industry and publishes standards for the design, manufacture and testing of choke valves. API-6A is the standard for well equipment and contains the requirements for choke valves used in oil and gas production. - American Society of Mechanical Engineers (ASME)

ASME is a professional organization for mechanical engineers and publishes standards for the design, manufacture and testing of valves, including choke valves. The ASME B16.34 standard covers the requirements for valves, including choke valves, used in industrial and commercial applications. - National Association of Corrosion Engineers (NACE)

NACE is a professional organization for corrosion engineers and publishes standards for materials and coatings used in the oil and gas industry, including choke valves.

These certification bodies have specific requirements for the design, materials, testing and documentation of choke valves, and manufacturers must meet these requirements to get their valves certified. This certification process involves testing choke valves to ensure that they meet the standards set by these organizations and are safe for use in their intended applications.

In addition to the certification bodies mentioned above, there are other international standards such as ISO, EN, etc. that may be used in specific regions or countries. It is important to check local regulations and standards to ensure that the valves meet the requirements for the specific application and location.

In summary, the main advantage of a choke valve is its ability to accurately control flow rate, which is essential for safe and efficient operation in many industries. Given the critical role the choke plays, selecting a choke that offers superior control and long life is paramount to success.

References..

masterflo.com

www.saigaogroup.com

Related Post(s)

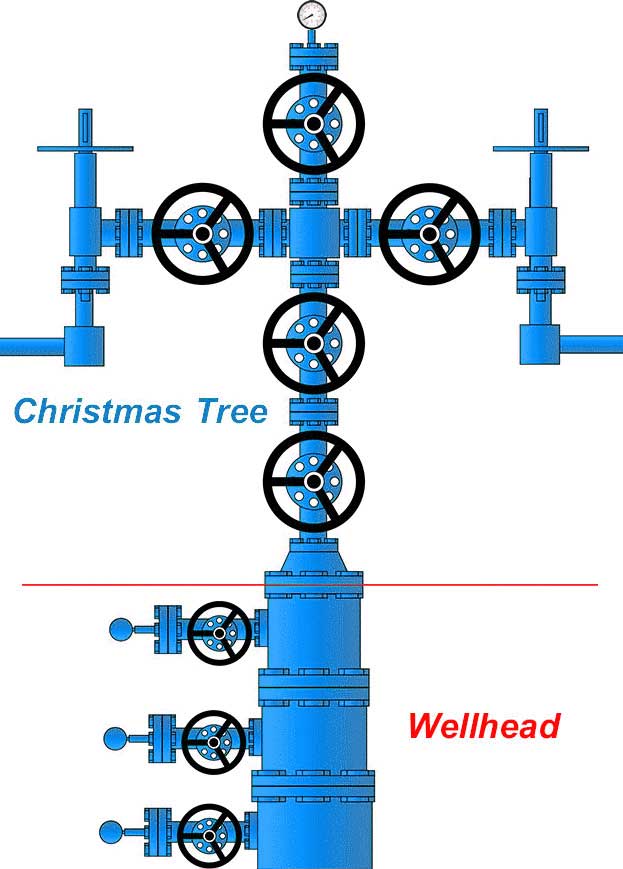

A wellhead is the component on the surface of an oil or gas well that provides the structural and pressure-containing interface for the drilling and production equipment. Surface pressure control is provided by a christmas tree installed on top of the wellhead, with isolation valves and choke devices to control the flow of well fluids during production...