|

Tubular Exchanger Manufacturers Association |

TEMA heat exchangers |

October 2025

The Tubular Exchanger Manufacturers Association (TEMA) has developed standards that define the design, manufacture, tolerances, installation, and maintenance of shell-and-tube heat exchangers.

This standard and the ASME Code are the most important guidelines for the design and manufacture of heat exchangers, together with customer specifications.

What are TEMA heat exchangers?

What is the purpose of TEMA?

The purpose of TEMA is to regulate the manufacture of shell and tube heat exchangers through the TEMA standard, thereby ensuring the safety and reliability of end-user equipment. TEMA standards are applied internationally to ensure that a heat exchanger is of high quality regardless of where it is manufactured.

TEMA standard

The design standards for shell and tube heat exchangers are specified in the document Standards of the Tubular Exchanger Manufacturers Association. The latest edition (the 10th) was published in 2019. At the time of publication of this article, the 11th edition is available.

There are three main TEMA classifications..

- TEMA C (General commercial applications)

- TEMA B (Chemical applications)

- TEMA R (Refinery applications)

Overall, the three are very similar.

TEMA C is the most commonly used and has the least stringent requirements, as it

is designed for general-purpose heat exchangers.

TEMA B and R are slightly more specialized to ensure that heat

exchangers are suitable for more demanding environments. They typically require features such as

limited gasket joints, increased minimum thicknesses, or tolerances for lighter materials.

What do the TEMA standards cover?

The TEMA standard comprises 10 sections ranging from nomenclature to the physical properties of fluids used in shell and tube heat exchangers.

- Nomenclature

- Fabrication Tolerances

- General Fabrication and Performance Information

- Installation, Operation, and Maintenance

- Mechanical Standards TEMA Class RCB Heat Exchangers

- Flow Induced Vibration

- Thermal Relations

- Physical Properties of Fluids

- General Information (e.g.: pipe, tube, fitting and flange dimensions, pressure-temperature ratings, conversion factors)

- Recommended Good Practice

Items not covered by the TEMA standard

The TEMA standard is designed to apply to shell and tube heat exchangers that do not exceed any of the following criteria..

- inside diameters of 100in

- production of nominal diameter, in. and design pressure, psi of 100,000

- a design pressure of 3000 psi*

TEMA nomenclature

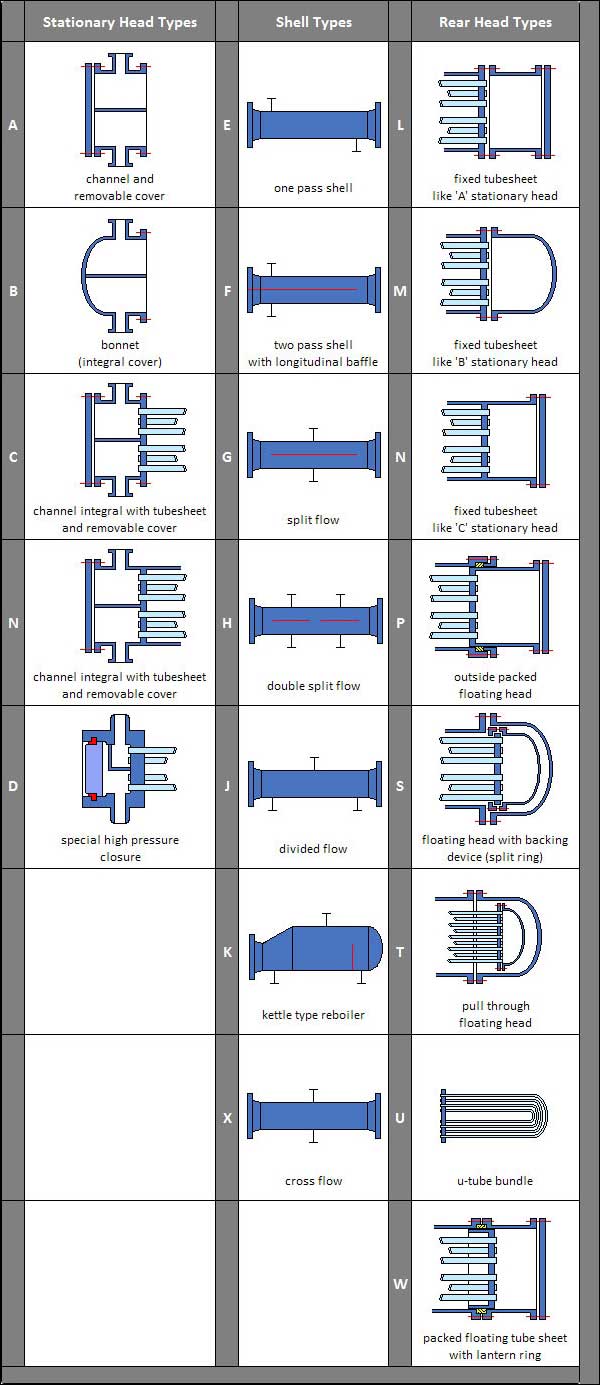

TEMA has not only established a series of standards for the manufacture of heat exchangers, but has also introduced a notation system. Since there are many mechanical design variants for front and rear heads and shells, the most important variants are identified by notations to provide clarity.

The first letter corresponds to the front head, the second to the shell type, and the third to the rear head type.

The image below shows the TEMA nomenclature by the Tubular Exchanger Manufacturers Association. More recent editions contain a more modern image, but the nomenclature is the same.

This page discusses some nomenclature.

Understanding TEMA designations can help determine the best configuration for shell and tube heat exchangers.

Reference.. www.sterlingtt.com

Related Post(s)

A plate Heat Exchanger is a unit which transfers heat continuously from one media to another media without adding energy to the process...