Logistics by the Numbers

Logistics Concept. The aim of Nord Stream's logistics concept was to supply the materials needed in an efficient, timely and thereby cost efficient manner and to minimise impacts on the sensitive ecosystem of the Baltic Sea. Low-emission means of transportation such as ships and trains were used.

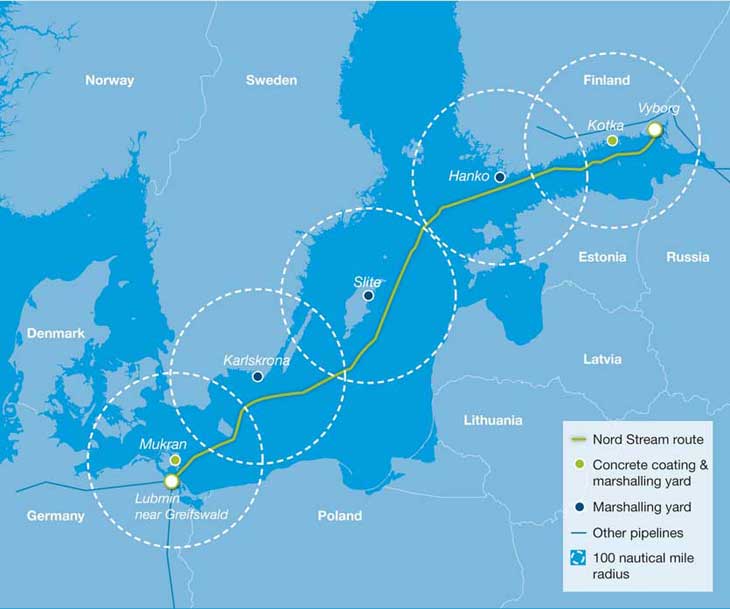

The locations for Nord Stream's coating plants and stockyards were selected to limit shipping distances to the pipelay vessels to less than 100 nautical miles, thereby allowing for daily round trips of the carrier vessels as well as transportation distances from the pipe mills.

More than 100 million euros were invested into the required infrastructure in the Baltic Sea region. Even after construction of the Nord Stream Pipeline is completed, these investments will provide significant benefits for the ports.

Major Logistics Partners. Nord Stream contracted EUPEC for concrete coating and logistics services in the Baltic Sea region. EUPEC has 40 years of experience in pipe coating.

DB Schenker Rail Deutschland AG and the Russian national railway provided services to transport steel pipes to the coating plants in Mukran and Kotka respectively.

The total contract value for concrete coating and logistics for the Nord Stream project amounted to about 650 million euros.

The handling and transport of pipes to the three marshalling yards in Karlskrona, Slite (both in Sweden) and Hanko (Finland) were provided by the Norwegian NorSea Group that has extensive experience with offshore projects.

At the end of the logistics chain was the Italian company Saipem S.p.A., which was commissioned to undertake offshore pipe laying of the two pipeline strings.

Nord Stream Logistics Concept. Nord Stream developed a high environmently-conscious logistic concept which guarantees that transport vessels have not to travel more than 100 nautical miles (185 kilometers). This is achieved by detailed planning of store capacites and sites. Kotka in the Gulf of Finland and Mukran on the German Island of Rügen were selected as logistics hubs for concrete weight coating and interim stockyards.This concept of short trips and environmentally friendly transport saves roughly 200,000 tonnes of carbon dioxide when compared against other options and the use of existing concrete coating plants.

Logistics Chain and Locations. To ensure that the pipeline was laid as efficiently as possible, five ports were chosen based on comprehensive evaluation of environmental and economic criteria.

Kotka on the coast of Finland and Mukran on the Island of Rügen (Germany) were selected as locations for the concrete weight coating and interim stockyards.

The ports of Hanko (Finland), Karlskrona (Sweden) and Slite on the island of Gotland (Sweden) were selected as interim stockyards to ensure short transport distances to the pipeline route.

Infrastructure investments for the Nord Stream project provided substantial support for the development of the five sites, giving a boost to the regional economy and labour markets. This investment will also have indirect benefits for business development and employment at all these locations, as well as long-lasting benefits resulting from improvements to their infrastructure.

Pipe Production

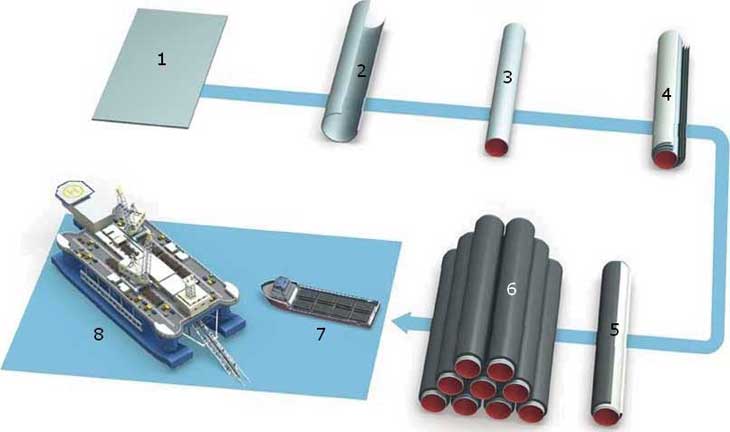

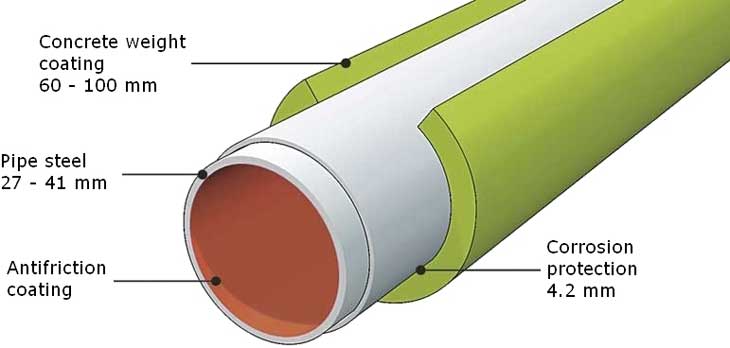

- Production of the approximately 202,000 pipes included plate production, pipe milling, welding, stretching, treatment of pipe ends (chamfering and bevelling) and quality control.

- After quality control, all pipes received an internal anti-friction coating and an external anti-corrosion coating.

- Pipes for the first pipeline were produced by the German company EUROPIPE GmbH (75 percent) and Russian OMK (25 percent).

- For the supply of steel pipes for the second pipeline, Nord Stream commissioned EUROPIPE (65 percent) and OMK (25 percent) as well as Japanese Sumitomo (10 percent).

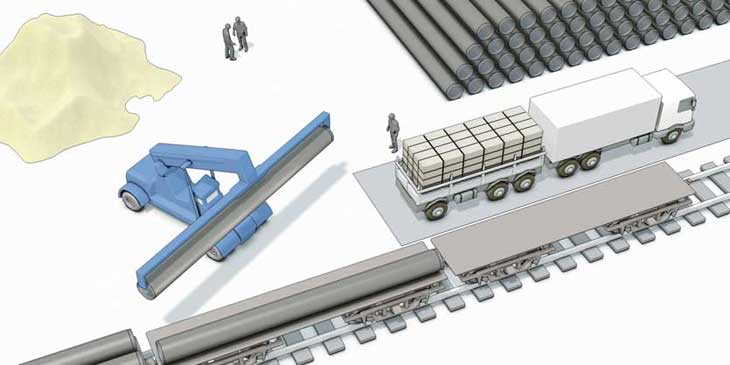

Pipes reach Mukran and Kotka by rail and ship. Cement, magnetite, sand and aggregate are delivered for the concrete coating.

Transportation

- After coating, the pipes were immediately transported to the concrete weight coating plants on the Baltic Sea coast - Mukran in Germany and Kotka in Finland.

- 95 percent of the pipes from the pipe mills in Mülheim an der Ruhr and Vyksa were transported by train to Mukran and Kotka respectively. Additionally, Sumitomo's deliveries arrived by ship from Japan.

After the steel pipes are concrete coated in Mukran and Kotka they are trans-shipped to interim marshalling yards.

Concrete Weight Coating and Storage

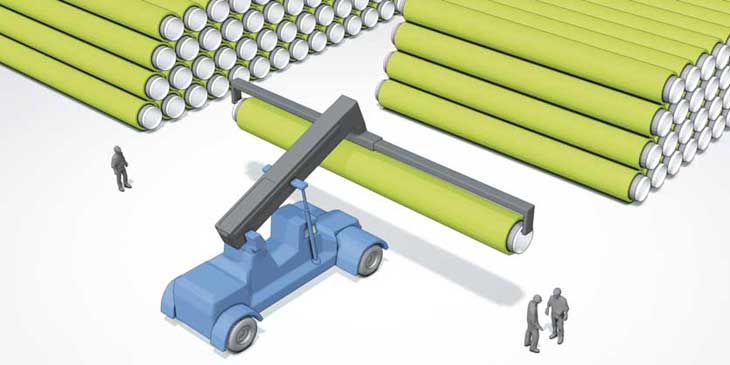

- After concrete coating, the weight of each of the pipe segments increased to up to 25 tonnes. The additional weight ensures stability of the pipeline on the seabed and also protects the pipeline against damage in the water, such as by bottom trawling equipment or backfilling.

Concrete coated pipes are stored at each of the five marshalling yards located strategically along the route.

Each 12.2 m pipe is coated with concrete, doubling its weight to 20-30 tonnes. The weight provides stability on the seabed.

Trans-shipment and Storage

- Out of Mukran, 30,000 pipes were shipped to Karlskrona and 56,500 to Slite for interim storage at the marshalling yards. Another 39,000 went directly to the pipelay vessels.

- Out of Kotka, 30,000 pipes were shipped to Hanko for interim storage while 45,500 went directly to the pipelay vessels.

Carrier vessels continuously deliver pipes to the laybarges to maintain a 24-hour construction schedule.

Pipe Laying

- Special pipe carrier vessels transported the pipe segments to the pipelay vessels.

- On board the pipelay vessels, the pipes were welded onto the pipeline, which was then progressively lowered to its designated place on the seabed.

Project Players

Nord Stream Gas Purchasers

- Gazprom Marketing and Trading Ltd, UK

- DONG Energy A/S

- GDF SUEZ S. A.

- WINGAS GmbH and Co. KG

- E.ON Ruhrgas AG

Logistics

- EUPEC

- Port of Sassnitz-Mukran

- Port of Kotka

- Port of Hanko

- Port of Slite

- Port of Karlskrona

Pipes and Materials

- EUROPIPE

- OMK

- Sumitomo

- Petrol Valves

Environmental Studies, Quality Management and Safety

- Marin Mätteknik

- Rambøll

- DoF

- PeterGaz

- ERM

- DNV

- FOGA

- SGS TÜV

Construction

- Saipem

- Allseas

- Van Oord

- Boskalis-Tideway

- Rohde Nielsen

Operations

- Technip

- Statoil

- Siemens

- IMPaC

Concrete weight coating & logistics services were provided by EUPEC PipeCoatings S.A. For the concrete weight coating new coating plants were constructed in Mukran (Germany) and Kotka (Finland). Rolls-Royce plc supplied eight industrial aeroderivative gas turbines driving centrifugal compressors for front-end gas boosting at the Vyborg (Portovaya) gas compressor station. Dresser-Rand Group supplied DATUM compressors and Siirtec Nigi SPA provided a gas treatment unit for the Portovaya station.

For the construction period, Nord Stream AG created a logistic center in Gotland. Other interim stock yards are located in Mukran, in Kotka, in Hanko (Finland) and in Karlshamn (Sweden).

Reference(s) for the images and text, is owned by Nord Stream AG